Hazardous Products (Toys) Regulations

C.R.C., c. 931

Regulations Respecting the Advertising, Sale and Importation of Hazardous Products (Toys)

Short Title

1 These Regulations may be cited as the Hazardous Products (Toys) Regulations.

Interpretation

2 In these Regulations,

- Act

Act means the Hazardous Products Act; (Loi)

- soft toy

soft toy includes a stuffed toy, a pliable rubber toy and a pliable plastic toy. (jouet mou)

General

3 (1) A person may advertise, sell or import into Canada a product included in any of items 13 to 20 of Part II of Schedule I to the Act only if that product meets the requirements of these Regulations.

(2) Any written statement or warning or other written information required by these Regulations shall appear in both the English and French languages.

- SOR/91-267, s. 1

Packaging

4 (1) A flexible film bag used to package any product described in paragraph 13(a) of Part II of Schedule I to the Act shall meet the following requirements:

(a) the opening of the bag shall be less than 14 inches in circumference; or

(b) the bag shall

(i) be made from film that is at least 0.75 mil thick, and

(ii) have printed legibly on it the following warning:

“PLASTIC BAGS CAN BE DANGEROUS. TO AVOID DANGER OF SUFFOCATION KEEP THIS BAG AWAY FROM BABIES AND CHILDREN.”

(2) The warning set out in paragraph (1)(b) may be expressed in different words if those words convey clearly the same warning.

- SOR/91-267, s. 2

Electrical Hazards

5 Every product described in paragraph 13(b) of Part II of Schedule I to the Act shall meet the requirements applicable to it that are set out in Canadian Standards Association Standard C22.2 No. 149-1972, entitled Electrically Operated Toys.

- SOR/78-393, s. 1

- SOR/91-267, s. 3

6 Every wood-burning electric tool included in paragraph 13(b) of Part II of Schedule I to the Act shall meet the requirements applicable to it that are set out in Canadian Standards Association Standard C22.2 No. 122-M1989, entitled Hand-Held Electrically Heated Tools.

- SOR/91-267, s. 3

Mechanical Hazards

7 No product included in paragraph 13(c) of Part II of Schedule I to the Act shall have a component or part, other than a component or part constructed entirely of soft textile fibre material, that

(a) is separable;

(b) may become detached with reasonably foreseeable use; and

(c) can be totally enclosed in the small parts cylinder described in Schedule VIII.

- SOR/91-267, s. 4

- SOR/2004-65, s. 3

8 Every product described in

(a) paragraph 13(d) of Part II of Schedule I to the Act shall have all exposed metal edges folded back or sprayed with or dipped in paint or otherwise treated so that all sharpness and burrs are eliminated;

(b) paragraph 13(e) of Part II of that Schedule shall have all ends of wire covered, turned in or turned back so that no sharp ends become exposed with reasonably foreseeable use;

(c) paragraph 13(f) of Part II of that Schedule shall have all of its plastic parts that would, on breaking, expose sharp edges,

(i) made sufficiently thick to resist breakage through reasonably foreseeable use, or

(ii) where such parts are necessarily thin because of the function of the product, made of inherently tough materials;

(d) paragraph 13(g) of Part II of that Schedule shall have all of its exposed wooden surfaces, edges and corners smoothly finished;

(e) paragraph 13(h) of Part II of that Schedule shall have all edges and corners of the glass smoothly finished;

(f) paragraph 13(i) of Part II of that Schedule shall have only such fasteners as, by reason of their type, size and manner of use, will not, with reasonably foreseeable use, cause personal injury and, without limiting the generality of the foregoing, shall have

(i) any nails and staples properly secured,

(ii) any flat head or oval head wood screws of the countersunk head type properly countersunk,

(iii) any wood screws free of all exposed burrs,

(iv) any fasteners in upholstering or upholstering-like application properly secured and of a type that, if exposed would not be a hazard, and

(v) any threaded bolts protected by acorn or similar nuts or protective caps, unless the bolts are so placed that they protrude into a protected area where contact with the threaded ends is not likely to occur;

(g) paragraph 13(j) of Part II of that Schedule shall have a safety stop or a locking device to prevent the unintentional collapse of the product;

(h) paragraph 13(k) of Part II of that Schedule shall have

(i) its spring-wound driving mechanism enclosed so that the moving parts thereof cannot be touched under reasonably foreseeable use,

(ii) an outer case that will withstand reasonable abuse if the product is so constructed that damage to the outer case would cause the mechanism to be exposed,

(iii) where a non-detachable winding key has been installed, such winding key of a shape and size that a child’s finger cannot become ensnared in it, and

(iv) where a detachable key or starting handle is to be used, a clearance space between the key or handle, when in place, and the body of the product, that is less than 1/16 inch (2 mm) or greater than 3/8 inch (10 mm);

(i) paragraph 13(l) of Part II of that Schedule shall have a rubber tip or other durable fitting placed on the leading end of the projectile component with sufficient security to withstand a pulling force of ten pounds (44.5 N);

(j) paragraph 13(m) of Part II of that Schedule shall have holes of sufficient size and number in each of two or more adjacent sides to prevent the suffocation of a child enclosed therein; and

(k) paragraph 13(n) of Part II of that Schedule shall stand level and firm when used.

- SOR/78-393, s. 2

- SOR/91-267, s. 5

Thermal Hazards

9 Every product described in paragraph 13(o) of Part II of Schedule I to the Act shall meet the thermal and labelling requirements applicable to it that are set out in Canadian Standards Association Standard C22.2 No. 149-1972, entitled Electrically Operated Toys.

- SOR/78-393, s. 3

- SOR/91-267, s. 6

Toxicological Hazards

10 Every product described in paragraph 13(p) of Part II of Schedule I to the Act shall meet at least one of the following requirements:

(a) the product, by reason of its nature, physical form, size or any other characteristic, shall be such that the toxic substance or the substance or part containing the toxic substance cannot be ingested, inhaled or absorbed through the skin;

(b) the total quantity of the available toxic substance shall not exceed one-hundredth of the acute oral or dermal median lethal dose, whichever is the lesser, calculated for a child having a body weight of 10 kg; or

(c) the toxicity of the toxic substance does not exceed the limits prescribed by Schedule I.

- SOR/78-393, s. 4(E)

- SOR/91-267, s. 7

11 Every product described in paragraph 13(q) of Part II of Schedule I to the Act shall meet at least one of the following requirements:

(a) the product, by reason of its nature or any characteristic, shall be such that the corrosive substance, irritant or sensitizer cannot come in contact with the skin; or

(b) the corrosive substance, irritant or sensitizer shall not be excessively corrosive or irritant or an excessively strong sensitizer as determined in accordance with the tests prescribed by Schedule II.

- SOR/91-267, s. 8

12 (1) Subject to subsection (2), resins, plasticizers, antioxidants, dyes, pigments and other substances and the grade, quality, quantity and proportions thereof used in manufacturing any plastic material used in any product included in paragraph 13(r) of Part II of Schedule I to the Act shall be those considered acceptable for use in the manufacture of food packaging materials and food containers.

(2) A substance, other than a heavy metal, a compound of a heavy metal or a substance set out in item 8 or 9 of Part I of Schedule I to the Act, may, subject to sections 10 and 11, be present in a plastic material referred to in subsection (1) in the amount of one per cent or less.

- SOR/91-267, s. 9

Specific Products

Dolls and Soft Toys

13 All parts, clothing or ornamentation attached to any product described in paragraph 14(a) of Part II of Schedule I to the Act shall be attached to the product in such a manner that no sharp edge or point will become exposed as a result of reasonably foreseeable use of the product.

- SOR/91-267, s. 10

14 All material used for stuffing any product described in paragraph 14(b) of Part II of Schedule I to the Act shall

(a) be clean and free from vermin;

(b) be free from hard and sharp foreign matter; and

(c) be non-toxic and non-irritant as required by Schedules I and II.

- SOR/91-267, s. 11

15 Every eye or nose referred to in paragraph 14(c) of Part II of Schedule I to the Act, except a part that is made entirely of felt or other soft textile material, shall be attached to the product in such a manner that

(a) the eye or nose cannot be gripped by a three-pronged claw hook referred to in Schedule III; or

(b) when tested in accordance with the method described in Schedule III, the eye or nose does not become detached.

- SOR/91-267, s. 12

16 (1) Subject to subsections (2) and (3), every product described in paragraph 14(d) of Part II of Schedule I to the Act shall, when tested in accordance with the test procedures set out in Schedule V, have a time of flame spread in excess of 7 seconds.

(2) Where, due to the small size of a product referred to in subsection (1), sufficient material, including any seam, cannot be removed from the product to provide at least one of the test specimens required in the test referred to in Schedule V and the exposed pile length is two inches or more, the product, after being

(a) subjected to the laundering procedure prescribed in item 5 of Schedule VII, if the textile material or natural fur is known to have a flame-retarding finish, or if preliminary testing indicates that such a finish may be present,

(b) dried in an oven for 30 minutes at 221°F (105°C) or for 120 minutes at 167°F (75°C),

(c) removed from the oven, and

(d) placed over a desiccant such as anhydrous calcium chloride in a desiccator until cool, but for not less than 15 minutes or more than two hours,

shall

(e) not flame upon a one-second impingement of the calibrated flame applied by the flammability tester specified in item 1 of Schedule VI; or

(f) self-extinguish within two seconds of the removal of the flame referred to in paragraph (d).

(3) Where, due to the small size of a product referred to in subsection (1), sufficient material, including any seam, cannot be removed from the product to provide at least one of the test specimens required in the test referred to in Schedule V and the exposed pile length is less than two inches, subsection (1) is not applicable to the product.

(4) [Revoked, SOR/80-312, s. 1]

- SOR/80-312, s. 1

- SOR/91-267, s. 13

17 (1) Subject to subsection (2), every product described in paragraph 14(e) of Part II of Schedule I to the Act shall have a time of flame spread in excess of 7 seconds,

(a) when tested in accordance with the test procedures set out in Schedule VII; or

(b) where, due to the short length of the yarn, sufficient material cannot be removed from the product to provide at least one of the test specimens required in the test procedures set out in Schedule VII, when tested in accordance with the test procedures set out in Schedule V.

(2) Where, due to the short length of the yarn and the small size of a product referred to in subsection (1), sufficient material, including any seam, cannot be removed from the product to provide at least one of the test specimens required in the test procedures set out in Schedule V, subsection (1) is not applicable to the product.

- SOR/91-267, s. 14

18 The hair or mane, or simulated hair or simulated mane, of every product described in paragraph 14(f) of Part II of Schedule I to the Act, after being

(a) subjected to the laundering procedure prescribed in item 5 of Schedule VII if the hair or mane, or simulated hair or simulated mane is known to have a flame-retarding finish, or if preliminary testing indicates that such a finish may be present,

(b) dried in an oven for 30 minutes at 221°F (105°C) or for 120 minutes at 167°F (75°C),

(c) removed from the oven, and

(d) placed over a desiccant such as anhydrous calcium chloride in a desiccator until cool, but for not less than 15 minutes or more than two hours,

shall

(e) not flame upon a one-second impingement of the calibrated flame applied by the flammability tester specified in item 1 of Schedule VI, or

(f) self-extinguish within two seconds of the removal of the flame referred to in paragraph (d).

- SOR/91-267, s. 15

19 Every squeaker, reed, valve or other similar device referred to in paragraph 14(g) of Part II of Schedule I to the Act that can be totally enclosed in the small parts cylinder shown in Schedule VIII shall be secured to the product in such a manner that it cannot come loose as a result of reasonably foreseeable use.

- SOR/91-267, s. 16

- SOR/2004-65, s. 4

20 Every product described in item 14 of Part II of Schedule I to the Act shall meet all such requirements prescribed by these Regulations in respect of products included in item 13 of Part II of that Schedule as are applicable to it.

- SOR/91-267, s. 16

Pull and Push Toys

21 Every product described in item 15 of Part II of Schedule I to the Act shall

(a) meet all such requirements prescribed by these Regulations in respect of products described in items 13 and 14 of Part II of that Schedule as are applicable to it; and

(b) have a protective tip placed on the end of the shaft-like handle thereof

(i) for the purpose of preventing puncture wounds, and

(ii) with sufficient security to withstand a pulling force of 10 pounds (44.5 N).

- SOR/78-393, s. 5

- SOR/91-267, s. 17

Toy Steam Engines

22 Every product included in item 16 of Part II of Schedule I to the Act shall meet such requirements prescribed by these Regulations in respect of products described in item 13 of Part II of that Schedule as are applicable to it.

- SOR/91-267, s. 18

23 (1) Toy steam engine boilers shall meet the following requirements:

(a) each boiler shall be fitted with a firmly installed spring valve or any other safety valve except a weight valve;

(b) the operating pressure of a safety valve shall not be more than one and one-half times the operating pressure of the steam boiler to which it is fitted; and

(c) each boiler shall be constructed to withstand, without rupture, a pressure that is at least three times the operating pressure of the boiler.

(2) For the purpose of subsection (1), the operating pressure of a boiler is the steam pressure in the boiler that adjusts itself after the steam engine has been running without a load.

Finger Paints

24 Every product included in item 17 of Part II of Schedule I to the Act shall

(a) be water-based; and

(b) meet such requirements prescribed by these Regulations in respect of products included in item 13 of Part II of that Schedule as are applicable to it.

- SOR/91-267, s. 19

Rattles

25 Every product included in item 18 of Part II of Schedule I to the Act shall be so constructed

(a) that no sharp wire will, with reasonably foreseeable use, become exposed; and

(b) that no part of the product and none of its components that can be removed by the application of a force of 50 Newtons (11.23 lbs.) or less or a torque of less than one Newton metre (8.85 in. lbs.) will impinge on the base of the template depicted in Schedule IX, when tested in accordance with the instructions set out in that Schedule.

- SOR/91-267, s. 20

Elastic

26 Every product described in item 19 of Part II of Schedule I to the Act shall meet at least one of the following requirements:

(a) its extensibility shall not be more than 75 per cent of its unstretched length; or

(b) its fully-stretched length shall not be more than 30 inches (0.75 m).

- SOR/91-267, s. 21

Batteries

27 Every product included in item 20 of Part II of Schedule I to the Act shall be constructed to withstand the test prescribed in Schedule IV without leakage.

- SOR/91-267, s. 22

SCHEDULE I(Sections 10 and 14)Permissible Limits of Toxicity

- 1

(1) For the purposes of paragraphs 10(c) and 14(c) of the Regulations, a substance shall be considered excessively toxic for humans if

(a) the acute oral LD50 value thereof for rat is 5 grams or less per kilogram body weight;

(b) the acute dermal LD50 value for rabbit is 2 grams or less per kilogram body weight; and

(c) where gas, vapour, mist or dust is likely to be encountered when the substance is used in any reasonably foreseeable manner, the LC50 value thereof for a one-hour exposure determined using rats, is 20,000 parts per million by volume of gas or vapor or less, or 200 milligrams per litre by volume of mist or dust or less.

(2) LD50 values are to be determined in conformity with good toxicological practice.

(3) The number of deaths during a 14-day period following dosage shall be used as the basis for calculation of the LD50 value.

(4) Sufficient animals shall be used to give a statistically significant result, which result shall be calculated using methods based upon good statistical practice.

(5) The methods used by C. I. Bliss (1938) and J. T. Litchfield and W. F. Wilcoxon (1949) are acceptable but other methods giving similar results may also be accepted.

2 The dermal LD50 value shall be determined in the following manner:

In the acute exposures the agent is held in contact with the skin by means of a sleeve for periods varying up to 24 hours. The sleeve, made of rubber dam or other impervious material, is so constructed that the ends are reinforced with additional strips and should fit snugly around the trunk of the animal. The ends of the sleeve are tucked, permitting the central portion to “balloon” and furnish a reservoir for the dose. The reservoir must have sufficient capacity to contain the dose without pressure. The dimensions of sleeves and the approximate body surface exposed to the test substance are given in the following table:

Dimensions of Sleeves for Acute Dermal Toxicity Test

(Test Animal Rabbits)

Measurements in centimetres Range of weight of animals (grams) Average area of exposure (cm.2) Average percentage of total body surface Diameter at ends Overall length 7.0 12.5 2,500–3,500 240 10.7 The sleeves may vary in size to accommodate smaller or larger subjects. In the testing of unctuous materials that adhere readily to the skin, mesh wire screen may be employed instead of the sleeve. The screen is padded and raised approximately 2 centimetres from the exposed skin. In the case of dry powder preparations, the skin and substance are moistened with physiological saline prior to exposure. The sleeve or screen is then slipped over the gauze which holds the dose applied to the skin. In the case of finely divided powders the measured dose is evenly distributed on cotton gauze, which is then secured to the area of exposure.

The animals are prepared by clipping the skin of the trunk free of hair. Approximately one half of the animals are further prepared by making epidermal abrasions every 2 centimetres or 3 centimetres longitudinally over the area of exposure. The abrasions are sufficiently deep to penetrate the stratum corneum (horny layer of the epidermis), but not to disturb the derma — that is, not to obtain bleeding.

The sleeve is slipped onto the animal, that is then placed in a comfortable but immobilized position in a multiple animal holder. Selected doses of liquids and solutions are introduced under the sleeve. If there is slight leakage from the sleeve, which may occur during the first few hours of exposure, it is collected and reapplied. Dosage levels are adjusted in subsequent exposures (if necessary) to enable a calculation of a dose that would be fatal to 50 per cent of the animals. This can be determined from mortality ratios obtained at various doses employed. At the end of 24 hours the sleeves or screens are removed, the volume of unabsorbed material, if any, is measured, and the skin reactions are noted. The subjects are cleaned by thorough wiping, observed for gross symptoms of poisoning, and then observed for two weeks.

3 For the purposes of this schedule, “LD50” means the dose that will kill 50 per cent of test animals under the specified conditions of test; and “LC50” means the concentration of gas and vapour that will kill 50 per cent of test animals under the specified conditions of test.

4 The methods referred to in subsection 1(5) are described in publications as follows:

(a) C.I. Bliss, The determination of the dosage-mortality curve from small numbers, Quarterly Journal of Pharmacy and Pharmacology, 1939, Volume 11, page 192; and

(b) J.T. Litchfield and W.F. Wilcoxon, A simplified method of evaluating dose-effect experiments, Journal of Pharmacology and Experimental Therapeutics, 1949, Volume 96, page 99.

SCHEDULE II(Sections 11 and 14)Criteria for Deciding if a Substance Is Excessively Corrosive or Irritant or an Excessively Strong Sensitizer

1 A substance or mixture of substances shall be considered not excessively irritant for the purposes of section 11 and paragraph 14(c) of the Regulations if it is not excessively irritant to

(a) the eye judged on human experience or based upon the test method described hereunder; and

(b) the skin judged on human experience or based upon the test method described hereunder.

Method for Testing Eye Irritant Properties

- 2

(1) Six albino rabbits are used for each test substance. Animal facilities for such procedures shall be so designed and maintained as to exclude sawdust, wood ships, or other extraneous materials that might produce eye irritation. Both eyes of each animal in the test group shall be examined before testing, and only those animals without eye defects or irritation shall be used. The animal is held firmly but gently until quiet. The test material is placed in one eye of each animal by gently pulling the lower lid away from the eyeball to form a cup into which the test substance is dropped. The lids are then gently held together for one second and the animal is released. The other eye, remaining untreated, serves as a control. For testing liquids, 0.1 millilitre is used. For solids or pastes, 100 milligrams of the test substance is used, except that for substances in flake, granule, powder or other particulate form the amount that has a volume of 0.1 millilitre (after compacting as much as possible without crushing or altering the individual particles, such as by tapping the measuring container) shall be used whenever this volume weighs less than 100 milligrams. In such a case, the weight of the 0.1 millilitre test dose should be recorded. The eyes are not washed following instillation of test material except as noted below.

(2) The eyes are examined and the grade of ocular reaction is recorded at 24, 48, and 72 hours. Reading of reactions is facilitated by use of a binocular loupe, hand slit-lamp, or other expert means. After the recording of observations at 24 hours, any or all eyes may be further examined after applying fluorescein. For this optional test, one drop of fluorescein sodium ophthalmic solution U.S.P. or equivalent is dropped directly on the cornea. After flushing out the excess fluorescein with sodium chloride solution U.S.P. or equivalent, injured areas of the cornea appear yellow; this is best visualized in a darkened room under ultraviolet illumination. Any or all eyes may be washed with sodium chloride solution U.S.P. or equivalent after the 24-hour reading.

(3) An animal shall be considered as exhibiting an excessive reaction if the test substance produces at any of the readings ulceration of the cornea (other than a fine stippling), or opacity of the cornea (other than a slight dulling of the normal luster), or inflammation of the iris (other than a slight deepening of the folds (or rugae) or a slight circumcorneal injection of the blood vessels), or if such substance produces in the conjunctivae (excluding the cornea and iris) an obvious swelling with partial eversion of the lids or a diffuse crimson-red with individual vessels not easily discernible.

(4) The test shall be considered positive if four or more of the animals in the test group exhibit a positive reaction. If only one animal exhibits a positive reaction, the test shall be regarded as negative. If two or three animals exhibit a positive reaction, the test is repeated using a different group of six animals. The second test shall be considered positive if three or more of the animals exhibit a positive reaction. If only one or two animals in the second test exhibit a positive reaction, the test shall be repeated with a different group of six animals. Should a third test be needed, the substance will be regarded as excessively irritant if any animal exhibits a positive response.

(5) To assist testing laboratories and other interested persons in interpreting the results obtained when a substance is tested in accordance with the method described in subsection (1) of this section, an “Illustrated Guide for Grading Eye Irritation by Hazardous Substances” is sold by the Superintendent of Documents, Government Printing Office, Washington, D.C., U.S.A. The guide contains colour plates depicting responses of varying intensity to specific test solutions. The grade of response and the substance used to produce the response will be indicated.

Method for Testing Skin Irritant Properties

- 3

(1) Primary irritation to the skin is measured by a patch-test technique on the abraded and intact skin of an albino rabbit, clipped free of hair. A minimum of six subjects are used in abraded and intact skin tests. Introduce under a square patch such as two single layers of surgical gauze, measuring 1 inch by 1 inch, 0.5 millilitre (in the case of liquids) or 0.5 gram (in the case of solids and semisolids) of the test substance. Dissolve solids in an appropriate solvent and apply the solution as for liquids. The animals are immobilized with patches secured in place by adhesive tape. The entire trunk of the animal is then wrapped with an impervious material such as rubberized cloth for the 24-hour period of exposure. This material aids in maintaining the test patches in position and retards the evaporation of volatile substances. After 24 hours of exposure, the patches are removed and the resulting reactions are evaluated on the basis of the designated values in the following table:

Evaluation of skin reactions ValueFootnote for 1 Erythema and eschar formation: No erythema

0 Very slight erythema (barely perceptible)

1 Well-defined erythema

2 Moderate to severe erythema

3 Severe erythema (beet redness) to slight eschar formation (injuries in depth)

4 Edema formation: No edema

0 Very slight edema (barely perceptible)

1 Slight edema (edges of area well defined by definite raising)

2 Moderate edema (raised approximately one millimetre)

3 Severe edema (raised more than one millimetre and extending beyond the area of exposure)

4 Return to footnote 1The “value” recorded for each reading is the average value of the six or more animals subject to the test.

Readings are again made at the end of a total of 72 hours (48 hours after the first reading). An equal number of exposures are made on areas of skin that have been previously abraded. The abrasions are minor incisions through the stratum corneum, but not sufficiently deep to disturb the derma or to produce bleeding. Evaluate the reactions of the abraded skin at 24 hours and 72 hours, as described in this paragraph. Add the values for erythema and eschar formation at 24 hours and at 72 hours for intact skin to the values on abraded skin at 24 hours and at 72 hours (four values). Similarly, add the values for edema formation at 24 hours and at 72 hours for intact and abraded skin (four values). The total of the eight values is divided by four to give the primary irritation score. A score of 5 or more is indicative that the substance is excessively irritant.

(2) A substance shall not be considered to be excessively corrosive for the purposes of section 11 and paragraph 14(c) of the Regulations unless it causes visible destruction or irreversible changes in tissue at the site of the application.

(3) A substance shall be considered an excessively strong sensitizer for the purposes of section 11 and paragraph 14(c) of the Regulations if it causes an allergenic sensitization in a substantial number of persons who come into contact with it.

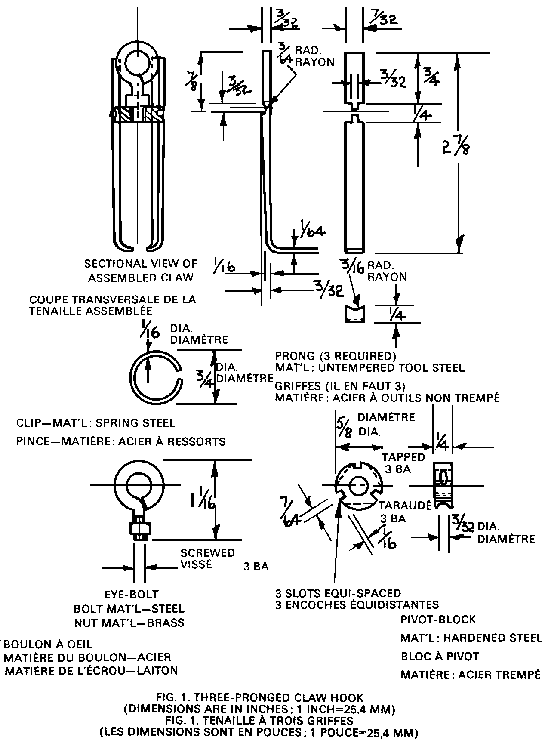

SCHEDULE III(Section 15)Method for Testing the Security of the Attachment of Eyes to Dolls and Soft Toys

1 Equipment

The following equipment is required:

(1) A weight of 20 lbs. (9 kg).

(2) A three-pronged claw hook (see Fig. 1).

(3) A supporting disc with a circular hole 1 inch (25.4 mm) in diameter.

(4) A supporting disc with a circular hole 1 1/2 inches (38.0 mm) in diameter.

2 Method of Test

(1) Attach the claw hook to the eye.

(2) Support the disc in a horizontal position and pass the claw through the 1-inch diameter hole. If there is insufficient clearance for the eye with the claw attached to pass through the 1-inch diameter hole, the disc with the 1 1/2 inch diameter hole should be used.

(3) Attach the weight to the claw hook, gradually releasing the weight over approximately 5 seconds and leaving it freely suspended for a period of 5 minutes measured from the time of first applying the load.

SCHEDULE IV(Section 27)Test Procedure for Batteries Used in Toys

1 Vibration Test

Test equipment as described in the Standard Method of Vibration Test for Shipping Containers ASTM D 999-68, a standard of the American Society for Testing and Materials.

Step 1

Place the battery on the table of the vibration tester in normal vertical position. Fences may be attached when required to prevent excessive rocking or moving on the table.

Step 2

Set the vibration frequency at the minimum speed sufficient to cause the battery to leave the table momentarily so that the shim may be inserted at least 4 inches between the bottom of the battery and the surface of the table. The piece of metal should be capable of being intermittently moved along one entire edge of the longest dimension of the battery.

Step 3

Vibrate the battery for 10 minutes. Rotate the battery placing another battery surface in contact with the table. Vibrate 10 minutes. Repeat for all battery surfaces.

Step 4

Inspect the exterior of the battery for visible damage. Check for presence of acid on battery surface.

2 Drop Test

1 Test equipment as described in the Standard Method of Drop Test for Shipping Containers ASTM D 775-61, a standard of the American Society for Testing and Materials, or in the Drop Test for Fibreboard Shipping Containers, No. T. 802m-44, a standard of the Technical Association of the Pulp and Paper Industry, United States of America.

2 Test Procedure

Step 1

With the battery in its normal position, face one end of the container and identify the surfaces as follows:

(1) top as 1;

(2) right side as 2;

(3) bottom as 3;

(4) left side as 4;

(5) near end as 5;

(6) far end as 6.

Step 2

Identify edges by the numbers of those two surfaces forming that edge. For example, the edge formed by the top and right side is identified as 1-2.

Step 3

Identify corners by the numbers of those three surfaces which meet to form that corner. For example, the corner formed by the right side, bottom, and near end is identified as 2-3-5.

Step 4

The drop height shall be as follows:

(1) Battery less than 50 pounds — 18 inches. NO ALTERNATIVE.

Step 5

Drop battery as specified under Step 4 in the following sequence:

(1) the 2-3-5 corner;

(2) the shortest edge radiating from that corner;

(3) the next longest edge radiating from that corner;

(4) the longest edge radiating from that corner;

(5) flat on one of the smallest faces;

(6) flat on the opposite small face;

(7) flat on one of the medium faces;

(8) flat on the opposite medium face;

(9) flat on one of the largest faces;

(10) flat on the opposite large face.

Step 6

Inspect the exterior of the battery for visible damage; check for presence of acid on battery surface.

SCHEDULE V(Sections 16 and 17)Test Procedure for Dolls, Plush Toys and Soft Toys That Are Covered with a Flat or Raised Fibre Textile Material or Natural Fur

The covering shall be removed from the product and tested in accordance with the following test method:

Scope

1 This method covers the evaluation of the flammability of outer coverings of dolls, soft toys, plush toys and any other toys covered with a flat or raised fibre textile material or natural fur, including dolls’ clothing. The term “raised fibre surface” in the method means a napped, pile, tufted, flocked or similar surface.

Principle

2 Specimens cut from the outer covering are prepared by brushing where they have a raised fibre surface, by laundering, where they have a flame-retarding finish, and by drying. The dried specimen is held in a special apparatus at an angle of 45 degrees, a standardized flame is applied to the surface near the lower end for 1 second and the time required for flaming to proceed up the specimen a distance of 5 inches (127 mm) is recorded.

Apparatus and Materials

- 3

(1) Flammability tester as described in item 1 of Schedule VI.

(2) Brushing device as described in item 2 of Schedule VI.

(3) Laboratory drying oven.

(4) Desiccator, 250 mm in diameter.

(5) Calcium chloride, anhydrous.

(6) Butane, cp.

(7) AATCC Standard Detergent 124.

(8) Cotton sewing thread, No. 50, mercerized.

Test Specimens

- 4

(1) Five test specimens, each measuring 2 by 6 inches (51 by 152 mm) shall be selected from that part of the outer covering that burns most rapidly.

(2) Where possible, in order to select the specimens that burn most rapidly, determine the direction in which to cut the specimens and the part of the outer covering from which to select the specimens by making preliminary trials, in accordance with the prescribed test procedure, with specimens cut in different directions and from different locations in the outer covering. The test specimens shall then be cut in that direction and from that location on the product.

(3) For textiles having a raised fibre surface, the long dimension usually is in the direction of lay of the surface fibres.

(4) Where the outer covering is an assembly and a portion thereof, including seams, cannot be removed therefrom in a size large enough to provide the required specimen, pieces may be removed and reassembled in the specimen holder in the same manner as in the original assembly, if the pieces are of such size as to be securely held in place by the specimen holder.

(5) If the outer covering is known to have a flame-retarding finish, or if preliminary testing indicates that such a finish may be present, the outer covering shall be subjected to the laundering procedure prescribed in item 5.

Laundering Procedure

- 5

(1) Textile materials known to have, or suspected of having, a flame-retarding finish applied to them shall be preconditioned by being subjected to the following washing and drying procedure.

(2) Prepare a bath solution consisting of water of hardness not greater than 5 grains of calcium carbonate per imperial gallon in an amount 30 times the weight of the sample from which the specimens are to be taken and AATCC Standard Detergent 124 in an amount equal to 15 per cent of the weight of the sample. The temperature of the bath solution must be 95° to 100°F (35° to 38°C).

(3) Immerse the sample from which the specimens are to be taken and allow to soak for 3 minutes. Work the sample gently by hand for 2 minutes, squeezing the bath solution through the part of the sample to be tested.

(4) Rinse the sample three times in water of hardness not greater than 5 grains of calcium carbonate per imperial gallon in an amount 30 times the weight of the sample from which the specimens are to be taken. The temperature of the rinse water must be 80°F (27°C). Immerse and gently squeeze the sample in the first rinsing bath for 1 minute and in the second and third baths for 2 minutes each.

(5) Remove excess water from the sample after each bath by squeezing gently and after the final rinsing bath blot out as much moisture as possible using paper towels or cotton terrycloth.

(6) Lay the sample flat to dry at ambient temperature, 65° to 75°F (18° to 24°C).

Preparation of Specimens

- 6

(1) Marking and Cutting Specimens. Five specimens, each 2 by 6 inches (51 by 152 mm), shall be marked out on the surface of the material opposite that to be tested with the longer dimension in the direction in which burning is most rapid, as established in the preliminary trials (subitem 4(2)). The end of each specimen toward which flame spread is most rapid shall be identified by attaching a staple to it. The specimens shall then be cut from the material.

(2) Brushing and Drying Specimens. Each specimen having a raised fibre surface shall be brushed once against the lay of the surface fibres with the brushing device shown in Fig. 2 of Schedule VI. Specimens not having a raised fibre surface do not require brushing.

(3) Each specimen shall be clamped individually in the specimen holders of the flammability tester (Fig. 1 of Schedule VI) so that the stapled end will be in the upper position during the test to ensure that the specimen is mounted in the direction in which burning is most rapid. The mounted specimen shall then be dried in a horizontal position in an oven for 30 minutes at 221°F (105°C) or for 120 minutes at 167°F (75°C), removed from the oven and placed over anhydrous calcium chloride in a desiccator until cool, but for not less than 15 minutes nor more than 2 hours.

Procedure

- 7

(1) Adjust the position of the rack of the flammability tester with a holder and trial specimen (not a prepared specimen) in a position so that the tip of the indicator touches the face of the specimen.

(2) Open the control valve of the fuel supply and allow approximately 5 minutes for the air to be driven from the fuel line. Ignite the gas and, with the door closed as far as possible, adjust the flame to a length of 5/8 inch (16 mm) measured from its tip to the opening in the gas nozzle.

(3) Remove a mounted specimen from the desiccator and place it in position on the rack in the chamber of the apparatus. The flame should be impinged on the test specimen within 45 seconds of the time it was removed from the desiccator. String the stop cord (No. 50 cotton sewing thread) through the guides in the upper plate of the specimen holder, across the top of the specimen, through the guides at the rear of the chamber and over the guide ring and attach the weight to the cord close to and just below the guide ring.

(4) Close the door of the apparatus. Set the stop watch at zero. Conduct the test in a draft-free room with the apparatus at room temperature.

(5) Bring the starting lever over to the extreme right and release it. This starts the timing mechanism and applies the flame to the specimen for a period of 1 second. Timing is automatic, starting upon application of the flame and ending when the weight is relesed by the burning of the stop cord.

(6) Record the time of flame spread for each specimen.

Interpretation of Results

- 8

(1) A specimen exhibiting either base burning or surface burning of sufficient intensity to sever the stop cord in 7 seconds or less is considered a failure.

(2) If one of the five specimens fails, test five additional specimens. Two failures out of 10 specimens results in a failure of the product to pass the test requirements.

SCHEDULE VI(Sections 16 and 18 and Schedules V and VII)Description of Apparatus

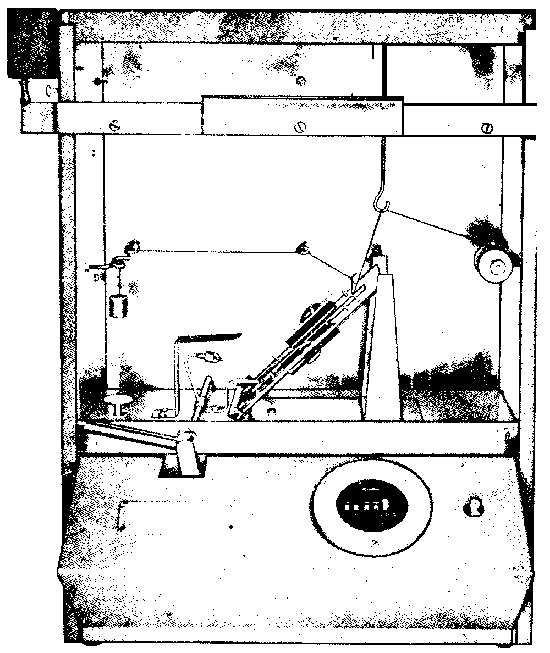

Flammability Tester

- 1

(1) The Flammability Tester (Fig. 1) consists of a draft-proof ventilated chamber enclosing a standardized ignition medium, a specimen rack and an automatic timing device.

(2) The draft-proof metal chamber prevents air circulation around the specimen rack and flame, but permits free ventilation for rapid oxidation. The chamber is 14 1/2 inches (268 mm) wide by 8 1/2 inches (216 mm) deep by 14 inches (256 mm) high. There are 12 one-half inch (12.7 mm) holes equidistant along the rear of the top closure. A ventilating strip is provided at the base of the sliding glass door in the front of the chamber.

(3) The specimen rack provides support for the frames in which the specimens are mounted. The angle of inclination is 45 degrees. Two guide pins projecting downward from the centre of the base of the rack travel in slots provided in the floor of the chamber so that adjustment can be made for the thickness of the specimen in relation to the flame front. An indicating finger is provided, the fore part of which touches the specimen when the rack is correctly adjusted.

(4) The specimen holder consists of two 1/16-inch (1.6 mm) matched metal plates with clamps mounted along the sides, between which the specimen is fixed. The plates are slotted and loosely pinned for alignment. The two plates of the holder cover all but 1 1/2 inches (38.1 mm) of the width of the specimen for its full length. The specimen holder is supported in the draft-proof chamber on the rack at an angle of 45 degrees. Five specimen holders are provided.

(5) Two control knobs hold the rack in test position. The knobs can be reached under the stage of the cabinet and permit forward and backward movements of the rack when loosened.

(6) The ignition medium consists of a spring-motor driven gas jet formed around a 26 gauge hypodermic needle. A trigger located in the front of the apparatus serves to wind the spring-motor when the machine is placed in operation. The gas jet is protected by a copper shield.

(7) The stop cord is stretched from the spool through suitable thread guides provided on the specimen frame and chamber walls, permitting the lacing of the cord in the proper position exactly 5 inches (127 mm) from the point where the centre of the ignition flame impinges on the test specimen. The stop cord is a No. 50 mercerized sewing thread.

(8) A weight attached by means of a clip to the stop cord, in dropping, actuates the stop motion.

(9) The glass door slides in grooves at the front of the cabinet. A knob moves the catch mechanism used to hold the sliding door in an open position for insertion of the test specimen holders.

(10) A sensitive fuel control valve regulates the fuel supply at the tank. The valve ends in a 1/2-inch male connection for attachment to the standard No. 4 butane cylinder of 2-pound (0.91 kg) capacity.

(11) The flow meter consists of a U-shaped glass tube cut into the gas line to register the gas pressure delivered to the microburner. Attached to the case wall behind the flow meter is a movable metal plate with two parallel horizontal lines properly spaced to indicate the desired gas pressure. When the pressure is off, the plate is so regulated that the liquid level in both sides of the U-shaped tube meets the lower line. When the apparatus is in operation, the pressure is so adjusted that the higher liquid level in the U-shaped tube meets the upper line.

(12) The starting lever is operated from left to right in one stroke and is released to operate the gas jet. A driving mechanism on the rear of the cabinet moves the gas jet to its most forward position and automatically starts the stop watch, by means of special attachments, at the moment of flame impact. The weight, when released by severance of the cord, drops onto a platform to stop the watch. Timing is read directly.

Brushing Device

- 2

(1) The brushing device (Fig. 2) consists of a base board over which a small carriage is drawn. This carriage runs on parallel tracks attached to the edges of the upper surface of the base board. The brush is hinged with pin hinges at the rear edge of the base board and rests on the carriage vertically with a pressure of 150 g.

(2) The brush consists of two rows of stiff nylon bristles mounted with the tufts in a staggered position. The bristles are 0.016 inch (0.41 mm) in diameter and 0.75 inch (19 mm) in length. There are 20 bristles per tuft and four tufts per inch. A clamp is attached to the forward edge of the movable carriage to permit holding the specimen on the carriage during the brushing operation.

(3) After the specimen has been put in place on the carriage and fastened by means of the clamp, the brush is raised, the carriage pushed to the rear and the brush lowered to the face of the specimen. The carriage is then drawn forward by hand at a uniform rate.

Modified Specimen Holder

3 The modified specimen holder consists of the holder described in subitem 1(4) with the addition of 38 gauge (B & S) spring steel wire securely attached across its width at 1/2 inch (1.27 cm) intervals, arranged so that the calibrated flame impinges at a point midway betweeen the two lowest wires.

FIGURE 1 — FLAMMABILITY TESTER

(Photograph courtesy of United States Testing Company, Inc., Hoboken, N.J., U.S.A.)

FIGURE 2 — BRUSHING DEVICE

(Photograph courtesy of United States Testing Company, Inc., Hoboken, N.J., U.S.A.)

- SOR/78-393, s. 6

SCHEDULE VII(Sections 16, 17 and 18)Test Procedure for Dolls, Plush Toys and Soft Toys Which in Whole or in Part Consist of or Are Covered with Spun Staple Yarn or Bulked Continuous Filament Yarn

Scope

1 This method covers the evaluation of the flammability of dolls, plush (raised fibre) toys and soft toys that

(a) have exposed surfaces consisting in whole or in part of yarn of spun staple or bulked continuous filament; or

(b) are constructed in whole or in part of parallel bundles of spun staple yarn or bulked continuous filament yarn that are exposed.

Principle

2 Specimens cut from the product are prepared by laundering, where they have a flame-retarding finish, and by drying. The dried specimen is held in a special apparatus at an angle of 45 degrees, a standardized flame is applied to the lower end for 1 second and the time required for flaming to proceed up the specimen a distance of 5 inches (127 mm) is recorded.

Apparatus and Materials

- 3

(1) Flammability tester as described in item 1 of Schedule VI.

(2) Brushing device described in item 2 of Schedule VI.

(3) Modified specimen holder described in item 3 of Schedule VI.

(4) Laboratory drying oven.

(5) Desiccator, 250 mm in diameter.

(6) Calcium chloride, anhydrous.

(7) Butane, cp.

(8) AATCC Standard Detergent 124.

(9) Cotton sewing thread, No. 50, mercerized.

Test Specimens

- 4

(1) If the yarn is known to have a flame-retarding finish, or if preliminary testing indicates that such a finish may be present, the yarn shall be subjected to the laundering procedure prescribed in item 5.

(2) Specimens of the yarn each measuring 6 inches (152 mm) in length shall be selected from that part of the outer covering that burns most rapidly.

Laundering Procedure

- 5

(1) Textile materials known to have, or suspected of having, a flame-retarding finish applied to them shall be preconditioned by being subjected to the following washing and drying procedure.

(2) Prepare a bath solution consisting of water of hardness not greater than 5 grains of calcium carbonate per imperial gallon in an amount 30 times the weight of the sample from which the specimens are to be taken and AATCC Standard Detergent 124 in an amount equal to 15 per cent of the weight of the sample. The temperature of the bath solution must be 95° to 100°F (35° to 38°C).

(3) Immerse the sample from which the specimens are to be taken and allow to soak for 3 minutes. Work the sample gently by hand for 2 minutes, squeezing the bath solution through the part of the sample to be tested.

(4) Rinse the sample three times in water of hardness not greater than 5 grains of calcium carbonate per imperial gallon in an amount 30 times the weight of the sample from which the specimens are to be taken. The temperature of the rinse water must be 80°F (27°C). Immerse and gently squeeze the sample in the first rinsing bath for 1 minute and in the second and third baths for 2 minutes each.

(5) Remove excess water from the sample after each bath by squeezing gently and after the final rinsing bath blot out as much moisture as possible using paper towels or cotton terrycloth.

(6) Lay the sample flat to dry at ambient temperature, 65° to 75°F (18° to 24°C).

Preparation of Specimens

6 Sufficient 6-inch lengths of the yarn shall be clamped in the modified specimen holder side by side without overlapping to form a specimen 1 inch wide in the centre of the holder. The loose ends may be tucked under the bottom wire to hold them in place. Five test specimens shall be prepared. The mounted test specimen shall then be dried in an oven for 30 minutes at 221°F (105°C) or 120 minutes at 167°F (75°C), removed from the oven and placed over anhydrous calcium chloride in a desiccator until cool, but for not less than 15 minutes or more than 2 hours.

Procedure

- 7

(1) Open the control valve of the fuel supply and allow approximately 5 minutes for the air to be driven from the fuel line. Ignite the gas and, with the door closed as far as possible, adjust the flame to a length of 5/8 inch (16 mm) measured from its tip to the opening in the gas nozzle.

(2) Remove a specimen from the desiccator and trim the lower ends to the length that will ensure that the end of the yarn will be contacted by the ignition flame.

(3) The test specimen should be tested within 45 seconds of the time it was removed from the desiccator. String the stop cord (No. 50 cotton sewing thread) through the guides in the upper plate of the specimen holder, across the top of the specimen, through the guides at the rear of the chamber and over the guide ring and attach the weight to the cord close to and just below the guide ring.

(4) Close the door of the apparatus. Set the stop watch at zero. Conduct the test in a draft-free room with the apparatus at room temperature.

(5) Bring the starting lever over to the extreme right and release it. This starts the timing mechanism and applies the flame to the specimen for a period of 1 second. Timing is automatic, starting upon application of the flame and ending when the weight is released by the burning of the stop cord.

(6) Record the time of flame spread for each specimen.

Interpretation of Results

- 8

(1) A specimen exhibiting burning of sufficient intensity to sever the stop cord in 7 seconds or less is considered a failure.

(2) If one of the five specimens fails, test five additional specimens. Two failures out of 10 specimens results in failure of the product to pass the test requirements.

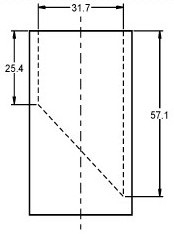

SCHEDULE VIII(Sections 7 and 19)Small Parts Cylinder

Any product or component of a product that can be totally enclosed in the following small parts cylinder using a force of not more than 1 lb. (0.45 kg) shall be considered an aspiration or an ingestion hazard or both:

Notes:

– Not to scale

– All dimensions in mm

- SOR/78-393, s. 7

- SOR/2004-65, ss. 5 to 7

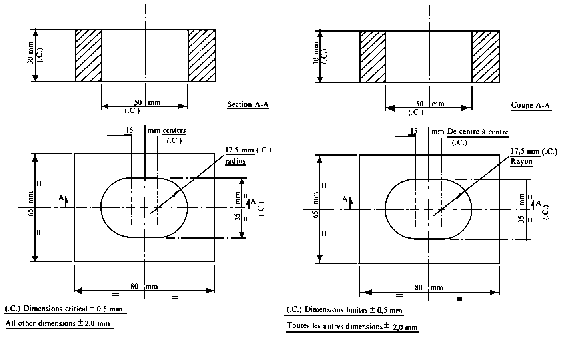

SCHEDULE IX(Section 25)Template To Determine Impaction Hazard of Rattles

Instructions

1 Place the template shown above on a horizontal surface.

2 Under its own weight, apply the product or component under test to the opening in the template.

- Date modified: