Marine Machinery Regulations

SOR/90-264

Registration 1990-05-01

Regulations Respecting the Construction, Installation and Inspection of Marine Machinery

P.C. 1990-744 1990-04-26

His Excellency the Governor General in Council, on the recommendation of the Minister of Transport, pursuant to section 338Footnote * of the Canada Shipping Act, is pleased hereby to revoke the Liquified Petroleum Gas Regulations, C.R.C., c. 1437, the Steamship Machinery Construction Order, C.R.C., c. 1490, the Steamship Machinery Construction Regulations, C.R.C., c. 1491 and the Steamship Machinery Inspection Regulations, C.R.C., c. 1492, and to make the annexed Regulations respecting the construction, installation and inspection of marine machinery, in substitution therefor.

Return to footnote *R.S., c. 6 (3rd Supp.), s. 47

Short Title

1 These Regulations may be cited as the Marine Machinery Regulations.

Interpretation

2 (1) In these Regulations,

- Act

Act means the Canada Shipping Act; (Loi)

- approved classification society

approved classification society means the American Bureau of Shipping, Bureau Veritas (Canada), Det norske Veritas, Lloyd’s Register of Shipping or Germanischer Lloyd; (société de classification agréée)

- assigned working pressure

assigned working pressure means the maximum fluid pressure to which the component with the lowest design working pressure in a system may be subjected and above which the system is protected from overpressure; (pression de service effective)

- auxiliary steering gear

auxiliary steering gear means the arrangements provided for effecting movement of the rudder of a ship in the event of failure of the main steering gear, but does not include the rudder stock, tiller or quadrant, or the component serving the same purpose as the tiller or quadrant, or, where fitted, the automatic-pilot system; (appareil à gouverner auxiliaire)

- boiler

boiler means a plant that generates steam or hot water under pressure by means of a flame, combustion gases or electrical heating elements, and includes the superheaters, economizers, valves and components necessary for the safety and operation of the plant; (chaudière)

- classification society

classification society means a society or association for the classification of ships; (société de classification)

- component

component means a unit or part of a unit that is identified in rules or codes and is to be installed as part of machinery; (élément)

- component inspection certificate

component inspection certificate means a certificate referred to in section 16; (certificat d’inspection d’élément)

- design working pressure

design working pressure means the maximum fluid pressure to which a component may be subjected during operating conditions; (pression de service nominale)

- fluid

fluid means a gas, vapour or liquid; (fluide)

- fuel oil unit

fuel oil unit means the facility, including pressure pumps, filters and heaters, dealing with oil at a pressure in excess of 180 kPa and used in the preparation of fuel oil for delivery to an oil-fired boiler or, where the oil is heated prior to delivery, to an internal combustion engine; (appareil à mazout)

- harmful substance

harmful substance[Repealed, SOR/2021-135, s. 65]

- inspection certificate

inspection certificate[Repealed, SOR/2021-135, s. 65]

- inspector

inspector[Repealed, SOR/2021-135, s. 65]

- launch

launch means a ship that has an open cockpit or a cockpit covered by a light trunk cabin in which passengers may be carried; (chaloupe)

- length

length means

(a) in the case of a Safety Convention passenger ship, the horizontal distance measured between perpendiculars erected at the extreme ends of the deepest subdivision load line,

(b) in the case of a ship, other than a Safety Convention passenger ship, that is required to be registered pursuant to the Act,

(i) the distance measured from the fore-part of the uppermost end of the stem to the aft side of the head of the stern post, except that where a stern post is not fitted to the ship, it is the distance from the fore-part of the uppermost end of the stem to the foreside of the head of the rudder stock,

(ii) where the ship has no rudder stock or has a rudder stock situated outside the hull at the stern, the distance measured from the foreside of the foremost permanent structure to the aft side of the aftermost permanent structure of the ship, but not including guards or rubbing strakes, or

(iii) where the ship is a double-ended ship, the distance measured from the aft side of the forward rudder stock to the foreside of the aft rudder stock, and

(c) in the case of a ship that is not required to be registered pursuant to the Act, the horizontal distance measured between perpendiculars erected at the extreme outside ends of the hull; (longueur)

- liquefied petroleum gas

liquefied petroleum gas means a liquefied inflammable gas that is composed predominantly of hydrocarbons or mixtures of hydrocarbons such as propane, propylene, butane, butylene or butadene, and that has a Reid vapour pressure exceeding 276 kPa absolute at 38° C; (gaz de pétrole liquéfié)

- local steering gear control system

local steering gear control system[Repealed, SOR/2021-135, s. 65]

- machinery spaces

machinery spaces means machinery spaces of category A and all other spaces containing propelling machinery, steering gears, boilers, steam and internal combustion engines, generators and major electrical machinery, oil filling stations, refrigerating, stabilizing, ventilation and air-conditioning machinery, and similar spaces, and trunks to the spaces; (tranche des machines)

- machinery spaces of category A

machinery spaces of category A means

(a) spaces that contain

(i) internal combustion-type machinery used for main propulsion or, where the aggregate of total power output is not less than 373 kW, for purposes other than main propulsion,

(ii) an oil-fired boiler, or

(iii) a fuel oil unit, and

(b) trunks to spaces referred to in paragraph (a); (tranche des machines de catégorie A)

- main steering gear

main steering gear means the main steering gear power unit and actuator by which torque is applied to the rudder stock for the purposes of effecting movement of the rudder to steer a ship; (appareil à gouverner principal)

- major repairs

major repairs means repairs or alterations to machinery that substantially alter the capacity, size or type of the machinery; (réparations majeures)

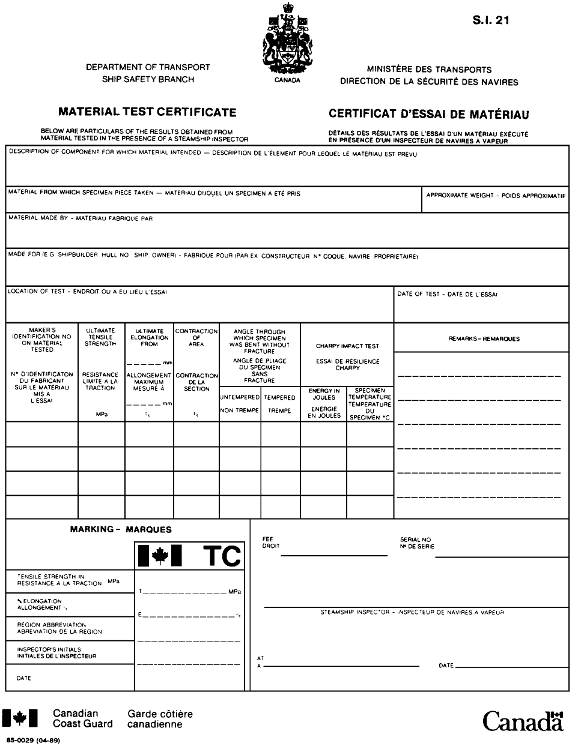

- material test certificate

material test certificate means a certificate referred to in section 10; (certificat d’essai de matériau)

- periodic general inspection

periodic general inspection[Repealed, SOR/2021-135, s. 65]

- periodic special inspection

periodic special inspection[Repealed, SOR/2021-135, s. 65]

- pressure vessel

pressure vessel[Repealed, SOR/2021-135, s. 65]

- remote steering gear control system

remote steering gear control system means the system by which required rudder movements are transmitted to the steering gear power unit controls from the bridge or another location in a ship, excluding the steering gear compartment; (système de commande à distance de l’appareil à gouverner)

- rudder actuator

rudder actuator means a unit transmitting torque to a rudder stock

(a) through an externally connected tiller, quadrant or similar component, or

(b) directly through an integrally housed vane or similar component; (actionneur de gouvernail)

- rules or codes

rules or codes means rules, regulations or codes relating to the construction, installation and inspection of marine machinery, issued by an approved classification society; (règles ou codes)

- shipside door-operating mechanism

shipside door-operating mechanism[Repealed, SOR/2021-135, s. 65]

- steering gear power unit

steering gear power unit means

(a) in the case of an electric steering gear, an electric motor and its associated electrical arrangements,

(b) in the case of an electro-hydraulic steering gear, an electric motor, and its associated electrical arrangements and the connected hydraulic pump, and

(c) in the case of a hydraulic steering gear, the driving engine and connected hydraulic pump; (groupe moteur d’appareil à gouverner)

- test pressure

test pressure means the maximum pressure to which the fluid in a component or system may be subjected during inspection; (pression d’essai)

- unfired pressure vessel

unfired pressure vessel means a container subjected to internal or external pressure, where the pressure is produced without the application of heat from an external source or by the application of heat from an indirect source or by any combination thereof, and includes condensers, evaporators, air receivers, hydro-pneumatic tanks, hydraulic accumulators, heat exchangers and similar components, but does not include cooling or heating spaces of engines, pumps, compressors, piping and similar components; (récipient sous pression non chauffé)

- windlass

windlass means the machinery and arrangements principally employed in the lowering and raising of the anchors of a ship, but does not include the anchors and cables. (guindeau)

(2) The units of measurement used in these Regulations are as defined in the Metric Practice Guide published by the Canadian Standards Association.

(3) Unless specifically stated otherwise, all prescribed pressures are gauge pressures.

- SOR/2002-428, s. 1

- SOR/2021-135, s. 65

Application

3 (1) Subject to subsection (2), these Regulations apply in respect of every ship as defined in Part XV of the Act.

(2) These Regulations do not apply in respect of a pleasure yacht or a non-passenger, non-self-propelled ship, except in respect of

(a) propulsion system boilers on board a pleasure yacht, where the yacht is in excess of five tons gross tonnage; and

(b) boilers and compressed air receivers on board a non-passenger, non-self-propelled ship carrying a crew where the ship

(i) may operate or ply on voyages more than 15 miles from land, or

(ii) does not operate or ply on voyages more than 15 miles from land and the boilers or compressed air receivers have an assigned working pressure in excess of 103 kPa.

(3) Despite subsection (1), these Regulations do not apply in respect of vessels to which the Vessel Construction and Equipment Regulations apply.

Construction and Installation Standards

4 (1) Any machinery referred to in Schedules I to XV that is constructed after the coming into force of these Regulations shall be constructed and installed in a ship in accordance with the following standards or specifications in force at the time the construction is commenced:

(a) the standards or specifications in the rules or codes under which the machinery is being constructed; and

(b) the design specifications set out in each item of Part I of the applicable schedule of Schedules I to XV and the general design specifications set out in Schedule XVI.

(2) In the event of any inconsistency between the standards or specifications referred to in paragraph (1)(a) and the specifications referred to in paragraph (1)(b), the specifications referred to in paragraph (1)(b) shall prevail.

(3) Any machinery referred to in subsection (1) that has been constructed in accordance with the standards or specifications in rules or codes of an approved classification society may be installed in a ship in accordance with the rules or codes of another approved classification society.

5 (1) Subject to subsection (2), major repairs to machinery referred to in Schedules I to XV that was constructed before or after the coming into force of these Regulations, including the reinstallation of components associated with the machinery following the major repairs, shall be made in accordance with the standards or specifications referred to in subsection 4(1) in force at the time the major repairs are commenced.

(2) Where making major repairs in accordance with subsection (1) would be impracticable or inappropriate, the major repairs may be made in accordance with the standards or specifications relating to construction set out in the regulations in force at the time construction of the machinery commenced.

6 [Repealed, SOR/2021-135, s. 66]

Material Testing and Marking

7 Specimen pieces of any material to be used in the construction of or repairs to machinery referred to in subsection 4(1) and required by the rules or codes under which the machinery is to be constructed to be tested prior to use shall be identified and shall, in the presence of an inspector, undergo, prior to the commencement of construction or repairs, the tests set out in those rules or codes.

- SOR/2015-161, s. 4

8 (1) An inspector referred to in section 7 shall, prior to the commencement of a test, be provided with evidence that shows that all the material testing equipment to be used is in correct operational condition and adjustment.

(2) The evidence referred to in subsection (1) may consist of current reports or certificates issued by an equipment testing organization that is accredited by the Standards Council of Canada.

9 On completion of the tests in the presence of an inspector, referred to in section 7, the material shall be permanently marked in the presence of that inspector with

(a) the information on the material test certificate set out in Schedule XVII under the heading “MARKING — MARQUES”; and

(b) the Federal Identity Symbol as printed on a stamp provided by the inspector.

10 An inspector shall issue a material test certificate in respect of a material in the form set out in Schedule XVII where

(a) the specimen pieces of the material meet the test requirements set out in the rules or codes referred to in section 7; and

(b) the material has been marked in accordance with section 9.

11 (1) Notwithstanding sections 7 and 9, an exclusive surveyor to an approved classification society or a metallurgist certified by a provincial government or by any other authority having similar certification standards may witness the tests and marking referred to in those sections.

(2) Where an exclusive surveyor or metallurgist referred to in subsection (1) witnesses the tests and marking of a material,

(a) the material test certificate shall include all testing information, bear the identification symbol of the employer of the exclusive surveyor or metallurgist and be signed by the exclusive surveyor or metallurgist; and

(b) the permanent marking on the material shall include the identification symbol of the employer of the exclusive surveyor or metallurgist.

12 [Repealed, SOR/2021-135, s. 67]

13 [Repealed, SOR/2021-135, s. 67]

14 [Repealed, SOR/2021-135, s. 67]

15 [Repealed, SOR/2021-135, s. 67]

Component Inspection Certificate and Marking

16 Subject to section 17, where an inspector has carried out a construction inspection of machinery in accordance with subsection 12(2), the inspector shall issue a component inspection certificate in the form set out in Schedule XVIII for each component of that machinery that is constructed in accordance with these Regulations.

17 Before issuing a component inspection certificate, an inspector shall ensure that the component is marked with the information on the certificate referred to in section 16 under the heading “MARKING — MARQUES”, including the Federal Identity Symbol.

18 (1) The marking referred to in section 17 shall be conspicuous and not readily effaced, covered or removed, and shall be located

(a) in the case of a hot-water boiler or a steam boiler, adjacent to an access or visual inspection opening;

(b) in the case of an unfired pressure vessel, on an end plate;

(c) in the case of a shaft, on the flange rim;

(d) in the case of a propeller, on the hub; and

(e) in the case of any other component, adjacent to the manufacturer’s permanent identification marking.

(2) Where a component cannot be marked on a location referred to in subsection (1) because marking on the location would be physically impossible or unsafe or the marking would not be readily visible, the inspector may accept another suitable location for the marking.

19 [Repealed, SOR/2021-135, s. 68]

20 [Repealed, SOR/2021-135, s. 68]

21 [Repealed, SOR/2021-135, s. 68]

22 [Repealed, SOR/2021-135, s. 68]

23 [Repealed, SOR/2021-135, s. 68]

24 [Repealed, SOR/2021-135, s. 68]

25 [Repealed, SOR/2021-135, s. 68]

SCHEDULE ISteam Boilers Having a Design Working Pressure Exceeding 350 kPa

PART I(Section 4)Design Specifications

| Item | Requirements |

|---|---|

| 1 | None. |

PARTS II to IV[Repealed, SOR/2021-135, s. 69]

SCHEDULE IILow-Pressure Steam Boilers Having a Design Working Pressure Not Exceeding 350 kPa and Hot-Water Boilers Having a Design Working Pressure Not Exceeding 1 100 kPa or a Design Temperature Not Exceeding 120°C

PART I(Section 4)Design Specifications

| Item | Requirements |

|---|---|

| 1 | None. |

PARTS II to IV[Repealed, SOR/2021-135, s. 70]

SCHEDULE IIIUnfired Pressure Vessels

PART I(Section 4)Design Specifications

| Item | Requirements |

|---|---|

| 1 | None. |

PARTS II to IV[Repealed, SOR/2021-135, s. 71]

SCHEDULE IVReciprocating Engines

PART I(Section 4)Design Specifications

DIVISION IInternal Combustion Oil Engines

| Item | Requirements |

|---|---|

| 1 | None. |

DIVISION IISteam Reciprocating Engines

| Item | Requirements |

|---|---|

| 1 | None. |

PARTS II to IV[Repealed, SOR/2021-135, s. 72]

- SOR/2015-161, ss. 5, 6(F)

- SOR/2021-135, s. 72

SCHEDULE VTurbine Engines

PART I(Section 4)Design Specifications

DIVISION ISteam Turbine Engines

| Item | Requirements |

|---|---|

| 1 | None. |

DIVISION IIGas Turbine Engines

| Item | Requirements |

|---|---|

| 1 | None. |

PARTS II to IV[Repealed, SOR/2021-135, s. 73]

- SOR/2015-161, s. 7(F)

- SOR/2021-135, s. 73

SCHEDULE VIReversing and Reduction Gearing, Shafting Systems and Propellers

PART I(Section 4)Design Specifications

DIVISION IReversing and Reduction Gearing

| Item | Requirements |

|---|---|

| 1 | None. |

DIVISION IIShafting Systems

| Item | Requirements |

|---|---|

| 1 | Screw shafts shall be made of

|

| 2 | The screw shaft shall have the propeller attached by means of

|

DIVISION IIIPropellers

| Item | Requirements |

|---|---|

| 1 | None. |

PARTS II to IV[Repealed, SOR/2021-135, s. 74]

- SOR/2015-161, ss. 8(E), 9(F)

- SOR/2021-135, s. 74

SCHEDULE VIISteering Systems, Shipside Components and Windlasses

PART I(Section 4)Design Specifications

DIVISION ISteering Systems

| Item | Requirements |

|---|---|

| 1 | A steering gear compartment shall

|

| 2 | All components and, in particular, non-duplicated essential components, shall be of sound and reliable construction, of adequate strength and protected against shock loading. |

| 3 | For essential components, bearings that are permanently lubricated or provided with lubrication fittings shall be utilized where required for the safe operation of the ship. |

| 4 | The pressure of the fluid for calculations to determine the scantlings of piping and steering gear components subjected to internal hydraulic pressure shall be at least 1.25 times the design working pressure under the operating conditions set out in item 9, taking into account any pressure that may exist in the low-pressure side of the system. |

| 5 | Where, due to dynamic loads on piping and steering gear components, pulsating pressures occur, the system design shall be such that fatigue does not cause material failure. |

| 6 | Relief valves shall be fitted to any part of the hydraulic system that can be isolated and in which pressure can be generated from the power source or from external forces. |

| 7 | Relief valve settings shall not exceed the design working pressure of the fluid set out in item 4 and the valves shall be of adequate size and arranged to avoid an undue rise in pressure above the design working pressure of the fluid. |

| Steering Gears | |

| 8 | Subject to items 19 and 20, the installation shall consist of totally independent main and auxiliary steering gears. |

| 9 | The main steering gear shall be designed, where the ship is at its deepest sea-going draft and

|

| 10 | A main steering gear shall be power-operated

|

| 11 | The auxiliary steering gear shall be designed, where the ship is at its deepest sea-going draft and running ahead one-half its maximum service speed or 7 knots, whichever is the greater, to put the rudder over from 15 degrees on one side to 15 degrees on the other side in not more than 60 seconds. |

| 12 | The auxiliary steering gear shall have the capacity to be brought safely and rapidly into action in an emergency. |

| 13 | An auxiliary steering gear shall be power-operated

|

| 14 | A power-operated auxiliary steering gear unit and its associated control system and rudder angle indicator shall, where the rudder stock is required to be over 230 mm in diameter, excluding strengthening for navigation in ice, be provided automatically with an alternative power source within 45 seconds of the failure of the main power source, from

|

| 15 | The alternative power source referred to in item 14 shall

|

| 16 | Main and auxiliary steering gear power units shall be

|

| 17 | Hydraulic power-operated main and auxiliary steering gears shall be equipped with the following:

|

| 18 | Electric and electrohydraulic power-operated main and auxiliary steering gears shall meet the following requirements:

|

| 19 | An auxiliary steering gear is not required where main steering gear power units and connections are fitted in duplicate if

|

| 20 | An auxiliary steering gear is not required for double-ended ships with two independent steering systems, one fore and one aft, if in the case of failure of one of the steering systems the corresponding rudder can be safely and rapidly brought back to the centre line and kept steady in that position. |

| 21 | For every tanker, chemical tanker or gas carrier of 10,000 tons gross tonnage or more and every other ship of 70,000 tons gross tonnage or more, the main steering gear shall comprise two or more identical power units that meet the requirements of item 19. |

| 22 | Subject to item 23, every tanker, chemical tanker or gas carrier of 10,000 tons gross tonnage or more shall meet the following requirements:

|

| 23 | For tankers, chemical tankers or gas carriers of 10,000 tons gross tonnage or more, but of less than 100,000 tonnes deadweight, in the event of a single failure referred to in item 22 of a rudder actuator, the requirements set out in that item are not required to be met if

|

DIVISION IINon-Duplicated Rudder Actuators for Tankers, Chemical Tankers and Gas Carriers of 10,000 Tons Gross Tonnage or more but less than 100,000 Tonnes Deadweight

| Item | Requirements |

|---|---|

| 1 | Components that are subject to internal hydraulic pressure or that transmit mechanical forces to the rudder stock shall be made

|

| 2 | The design working pressure shall be at least equal to the greater of

|

| 3 | In determining the scantlings of components of rudder actuators subject to internal hydraulic pressure, the following stresses are permitted: Sm shall not exceed S1 shall not exceed Sb shall not exceed S1 + Sb shall not exceed Sm + Sb shall not exceed where

A and B are as follows: |

| 4 | Pressure-retaining components not requiring fatigue analysis and fracture mechanics analysis in accordance with subitem 7(d) of Division I of Part II are acceptable on the basis of a certified burst test and in that case, the detailed stress analysis required by subitem 7(c) of Division I of Part II is not required. |

| 5 | The minimum bursting pressure shall be calculated as follows: Pb = P. A sBa/SB where

|

| 6 | The construction shall minimize local concentrations of stress and all welded joints within the pressure boundary of a rudder actuator or connecting parts transmitting mechanical loads shall be of the full penetration type or of an equivalent strength. |

| 7 | Oil seals between non-moving components, forming part of the external pressure boundary, shall be of the metal-on-metal type or of an equivalent type. |

| 8 | Oil seals between moving components, forming part of the external pressure boundary, shall be duplicated, so that the failure of one seal does not render the actuator inoperative, or shall have sealing arrangements providing equivalent protection against leakage. |

| 9 | Isolating valves shall be fitted at the connection of pipes to the actuator and shall be directly mounted on the actuator. |

| 10 | Relief valves for protecting the rudder actuator against over-pressure as required by items 6 and 7 of Division I shall meet the following requirements:

|

| 11 | The rudder actuator shall be subjected to non-destructive testing in accordance with rules or codes to detect both surface flaws and volumetric flaws, and fracture mechanics analysis may be used for determining maximum allowable flaw size. |

DIVISION IIISteering Controls

| Item | Requirements |

|---|---|

| 1 | Steering-wheels or lever pointers shall

|

| 2 | A rudder direction and angle indicator, independent of the remote steering gear control system, shall be fitted on the bridge where the main steering system is power-operated or the length of the ship exceeds 20 m. |

| 3 | Main steering gears shall be controllable from the bridge and from an alternative location in the steering gear compartment or other suitable location taking into account operational and risk factors. |

| 4 | A rudder angle indicator shall be fitted at the alternative location referred to in item 3. |

| 5 | Subject to item 6, two independent remote control systems, not including the steering-wheel or lever, shall be fitted where a duplicate main steering gear system is fitted. |

| 6 | Except in a tanker, chemical tanker or gas carrier of 10,000 tons gross tonnage or more a second independent control system is not required to be fitted where the control system is a hydraulic telemotor. |

| 7 | The auxiliary steering gear shall be controllable from the steering gear compartment and, if power-operated, shall be operable from the bridge and independent of the main steering gear control system. |

| 8 | Any main and auxiliary steering gear control system operable from the bridge shall meet the following requirements:

|

| 9 | Duplicate steering gear control systems, including pipes, electric power circuits and their components shall be separated, as far as practicable, throughout their length. |

DIVISION IVShipside Components

| Item | Requirements |

|---|---|

| 1 | For ships required to operate in ice-covered waters where ice may choke sea-water inlets, maintenance of essential sea-water supply shall be maintained by

|

DIVISION VWindlasses

| Item | Requirements |

|---|---|

| 1 | None. |

PARTS II to IV[Repealed, SOR/2021-135, s. 75]

- SOR/2015-161, ss. 10(E), 11, 12(E), 13(E), 14(F), 15(E), 16(E)

- SOR/2021-135, s. 75

SCHEDULE VIIIRemote Control and Monitoring Systems in Periodically Unattended Machinery Spaces

PART I(Section 4)Design Specifications

DIVISION IApplication

| Item | Description of Ships |

|---|---|

| 1 | In this schedule, Group 1 ship means a ship in which machinery is controlled and monitored from the bridge and engineers do not maintain surveillance watch duties in the machinery spaces and that is certificated for the following voyages:

Group 2 ship means a ship in which machinery may be controlled from the bridge and at least one engineer is on watch in a remote central control room location only and that is certificated for the following voyages:

Group 3 ship means a ship

|

| 2 | This Schedule does not apply to Group 1, 2 or 3 ships that are

|

DIVISION IIGroup 1, 2 and 3 Ships

| Item | Requirements |

|---|---|

| 1 | Remote and automatic control and monitoring of machinery located in periodically unattended spaces shall offer the same level of safety from remote control locations as would be obtained if the machinery were arranged for continuous local manual control and monitoring by watchkeeping engineers. |

| 2 | Control, monitoring and safety devices and their location shall meet the requirements set out in rules or codes in respect of ship motion, structural vibration and atmospheric environment. |

| 3 | Every enclosed central control location shall have two means of access located remote from each other, except where such enclosures are so small that two means of access are impracticable. |

| 4 | Two sources of power to ensure continuous operation shall be provided for control, monitoring and alarm systems, and

|

| 5 | Failure of control, monitoring and alarm systems or their power supply shall activate an audible and visual alarm at the central control location. |

| 6 | An audible and visual alarm system shall be provided to indicate any fault requiring attention and shall

|

| 7 | The alarm system shall be equipped to indicate at the same time more than one fault and the acceptance of an alarm shall not inhibit another alarm. |

| 8 | Acceptance at either of the locations referred to in subitem 6(a) of an alarm shall be indicated at the location where the alarm was activated. |

| 9 | An audible alarm shall sound until it is accepted and the visual indication of the alarm shall remain until the fault has been corrected, after which the alarm system shall automatically reset to the normal operating condition. |

| 10 | Machinery controls shall be designed to remain accurate throughout the operating range and to have fail safe characteristics. |

| 11 | Machinery controls shall be robust and easy to operate, not cause undue stress in systems being controlled and operate in a logical direction and sequence with a detent at the stop or neutral position. |

| 12 | A safety system shall be provided to ensure that a serious malfunction in boiler and other machinery operations that presents an immediate danger initiates the automatic shut-down of the boiler or other machinery and activates an alarm, except that shut-down of the propulsion system shall only be automatically activated in cases that could lead to serious damage, complete breakdown or explosion. |

| 13 | Where arrangements for overriding the shut-down of the main propelling machinery are fitted, the arrangements shall be such as to preclude inadvertent operation, and visual means shall be provided to indicate when the override has been activated. |

| 14 | Remote-controlled machinery systems and periodically unattended machinery spaces shall be equipped as follows:

|

| 15 | A reliable means of voice communication shall be provided between the main machinery control location or propulsion machinery control location and the bridge, the engineers’ cabins and the engineers’ public rooms. |

| 16 | Propulsion machinery orders from the bridge shall be indicated in the main machinery control room or at the propulsion machinery control station. |

| 17 | Manuals for the proper operation and maintenance of remote control and monitoring systems, containing all necessary information for normal and emergency operation and maintenance shall be provided aboard ship. |

| 18 | Testing procedure manuals for remote control and monitoring systems shall be provided aboard ship and the testing procedures shall

|

DIVISION IIIGroup 1 and 2 Ships

| Item | Requirements | |

|---|---|---|

| Machinery | ||

| 1 | Internal combustion engines of 2250 kW or more or having cylinders of more than 300 mm bore shall be provided with crankcase oil mist detectors, engine-bearing temperature monitors or equivalent devices. | |

| 2 | Where internal combustion engines are used for main propulsion, means shall be provided to keep the starting air pressure at the level required to start the engine. | |

| 3 | The number of consecutive automatic attempts that fail to start an engine shall be limited in order to safeguard sufficient starting air pressure and an audible alarm set at a level that permits starting of the propulsion machinery shall be provided to indicate low starting air pressure. | |

| 4 | The main source of electrical power shall meet the following requirements:

| |

| 5 | Where electrical power is supplied simultaneously by more than one generator in parallel operation, provision shall be made in case of failure of one of the operating generator sets to keep the remaining generator sets in operation without overload to permit propulsion and steering, and to ensure the safety of the ship. | |

| 6 | Where stand-by machines are necessary for the operation of other auxiliary machinery essential to propulsion, automatic change-over devices shall be fitted. | |

| Controls and Alarms | ||

| 7 | Under all operating conditions the speed, direction of thrust and, where applicable, the pitch of the propeller shall be fully controllable by remote control from the bridge. | |

| 8 | The remote control shall be operated by a single control device for each independent propeller with automatic performance of all associated services without causing overload of the propulsion machinery. | |

| 9 | The main propulsion machinery shall be equipped with an emergency stopping device on the bridge that is independent of the bridge control system. | |

| 10 | The control system shall be such that the services needed for the operation of the main propulsion machinery and its auxiliaries are performed automatically. | |

| 11 | An audible and visual alarm shall be activated when the automatic change-over of the control power source is activated. | |

| 12 | An alarm system that meets the requirements of items 7 to 9 of Division II shall be provided for all pressures, temperatures, fluid levels and other data essential to the safe operation of the ship. | |

| 13 | A centralized control location shall be arranged with the necessary alarm panels and instrumentation to indicate that an alarm has been activated. | |

| 14 | Remote control of the propulsion machinery shall be possible only from one location at a time and inter-connected control positions are permitted at each location. | |

| 15 | At each location there shall be an indicator showing which location is in control of the propulsion machinery and the transfer of control between the bridge and machinery spaces shall be possible only in the main machinery space or in the machinery control room. | |

| 16 | The control system shall include means to prevent, when the system transfers control from one location to another, the propelling thrust from altering to the extent that control of the ship is endangered. | |

| 17 | All machinery essential for the safe operation of the ship shall be capable of being controlled locally. | |

| 18 | The design of the remote automatic control system shall be such that an alarm is given on failure of the system and, unless impracticable, the preset speed and direction of thrust of the propeller is maintained until local control is in operation. | |

| 19 | Indicators shall be fitted on the bridge for

| |

| 20 | Bilge wells in periodically unattended machinery spaces shall be located and monitored in such a way that the accumulation of liquids is detected at normal angles of trim and heel, and shall be large enough to easily accommodate normal drainage during an unattended period. | |

| 21 | Where the bilge pumps are capable of being started automatically, visual and audible alarms shall be provided to indicate when the influx of liquid is greater than the pump capacity or when the pump is operating more frequently than would be expected under normal conditions. | |

| 22 | Where automatic bilge pumps are fitted,

| |

| 23 | The position of the controls of any valve serving a sea inlet, a discharge below the water-line or a bilge injection system shall be located to allow adequate time for operation of the controls in case of an influx of water to the space, having regard to the time likely to be required to reach and operate the controls. | |

| 24 | Arrangements shall be made to operate the controls from a position above the level to which the unattended space might become flooded when the ship is fully loaded. | |

DIVISION IVGroup 3 Ships

SUBDIVISION I

| Item | Application |

|---|---|

| 1 | In this Division, the bridge control station includes the wheelhouse, its top and wings. |

SUBDIVISION II

| Item | Requirements | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Main and Auxiliary Machinery Controls | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | Control locations shall have a visual indicator to show when they are in command and the central control location shall have monitors and alarms in accordance with items 65 and 66. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | The machinery control arrangement shall be such that only one location can be in control at any one time, and with the exception of the override capability referred to in item 8, transfer of control from the central control location to local control shall not be possible until the receiving location has indicated its readiness to accept the intended transfer. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | All essential machinery shall be capable of being fully operated locally when remote or automatic control systems are not operating. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | Transfer to local control of machinery shall be easily and rapidly accomplished and any material or tools required to effect the transfer shall be permanently located at a convenient location adjacent to the machinery. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | Where an engine is arranged to start automatically or by remote control, interlocks shall be provided to prevent starting of the engine under conditions that could be hazardous to the machinery, which conditions shall include turning gear engaged, low lubricating-oil pressure and, where applicable, shaft brake engaged. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | Where an internal combustion engine is arranged to start automatically, the number of consecutive automatic attempts to start the engine without success shall be limited in order to safeguard sufficient starting air pressure or in the case of electric starting, sufficient battery power, for local attempts to start the engine. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Main Propulsion Systems | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | Means shall be provided at the central control location and locally at the engines themselves to stop the main propulsion engines in an emergency and the emergency stopping devices shall be independent of the normal control system and adequately protected against accidental damage or operation. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | Local control of the main propulsion engines shall have capability of overriding the remote control systems and there shall be an audible and visual alarm to alert the locations affected by an override in accordance with subitem 65(a)(i). | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | For ships of not more than 150 tons gross tonnage remote propulsion engine controls are not required to be power-operated and are not required to be in duplicate. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | Prolonged running of a main propulsion engine in a restricted speed range shall be prevented automatically or an indication of restricted speed ranges shall be posted at each control location. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Steering Systems | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 | In the event of failure of the main steering system there shall be an auxiliary system capable of being brought into operation from the central control location within 45 seconds. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Electrical Power Systems | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | In the event of failure of the electrical generator supplying ship service power where generated electrical energy is required for essential service, there shall be a stand-by generator capable of assuming all essential electrical load and, for ships in excess of 150 tons gross tonnage, the stand-by generator shall be arranged to assume the load automatically within 45 seconds. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Boilers and Hot-Air Heating Units | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | Steam and hot-water boilers, hot-air heating units and associated systems shall be capable of automatic operation and of meeting requirements within design limitations under all working conditions. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 | Automatic operation shall include, as applicable, controls and monitors for fuel flow and temperature, combustion air flow, burner flame, feed-water flow, feed-water contamination by salt or oil, boiler pressure and hot-air heating unit circulating air flow. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | The control and monitoring equipment shall be designed to prevent unsafe operation of the boiler or hot-air heating unit. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | Any failure of control and monitoring equipment shall prevent continued operation of the boiler or hot-air heating unit and cause the fuel supply to be cut off and an audible and visual alarm to be activated in accordance with subitem 65(e). | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | A master fuel oil shut-off valve shall be fitted in the fuel supply line and shall close automatically in the event of

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | A fuel oil shut-off valve shall be fitted to each burner in the fuel supply line and the valve shall close automatically in the case of flame failure or whenever the automatic program requires that the master fuel oil shut-off valve be closed. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19 | Automatic combustion controls shall be fitted to provide an adequate fuel-to-air ratio throughout the operational range. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | Where the system is designed to light the initial burner automatically or from a remote location, purging of the combustion chamber and convection spaces shall automatically take place for a period that is sufficient to ensure at least four changes of air, which period shall last at least 15 seconds. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 21 | Adequate air flow and the correct position of the air registers and dampers shall be indicated before the purging period starts. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 | Fuel oil may be ignited by an electrical spark generated by a transformer having an output of not less than 10,000 volts, a glow plug or a light-oil pilot flame that has been electrically ignited. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 23 | A means of ignition system described in item 22 shall be provided for burners that are automatically or remote controlled. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | The electrical ignition system shall be energized before or simultaneously with the introduction of fuel or light oil and shall remain energized during the trial-for-ignition period referred to in item 25. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | Where fuel or light oil is electrically ignited, the flame safeguard control system shall provide a trial-for-ignition period of not more than 15 seconds, during which fuel or light oil may be introduced to the ignition source and, if a flame is not established within 15 seconds, the oil supply valve shall close automatically. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 26 | Where fuel oil is ignited by a light-oil pilot flame, the flame safeguard control shall provide a trial-for-ignition period of not more than 15 seconds, during which fuel oil may be introduced to the pilot flame and if a fuel oil flame is not established within 15 seconds the fuel oil supply valve to the pilot flame shall close automatically. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 27 | Fuel oil shall not be supplied to a burner before the light-oil pilot flame has been confirmed. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | Flame safeguard controls of the thermostatic type operated by means of an open bi-metallic helix shall not be used. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 29 | A flame safeguard control shall be provided to each burner so that the fuel oil supply valve can be closed in not more than four seconds in the event of flame failure and the master fuel oil shut-off valve can be closed in the event of flame failure at all burners. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | The failure of a component in the flame safeguard control shall cause a shut-down of the burner and the design of the control shall prevent automatic restarting. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 31 | The flame safeguard control shall be fitted with an audible and visual alarm in the event of flame failure and the control shall require resetting for restart purposes. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | A low-fire interlock shall be fitted to a multi-burner boiler so that the lowest burner is ignited first, and the other burners shall not be ignited until the scanner indicates that there is a flame in the lowest burner. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Steam Boilers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 33 | Automatically operated steam boilers shall be fitted with water-level controls and low water-level limit controls. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 34 | Water-level controls and low water-level limit controls may be of the float, electrode probe, thermostatic expansion tube or thermo-hydraulic type. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | Water-level controls and low water-level limit controls shall be located to minimize the effect of the roll and pitch of the ship. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36 | The low water-level limit control shall close the master fuel oil shut-off valve when the water level falls to a minimum safe level visible in the gauge glass and the system may include a five-second time delay to avoid shut-down due to the rolling and pitching of the ship. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 37 | After operation of the low water-level limit control, manual resetting of the control shall be required before the boiler burners can be re-lit. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 38 | Float-operated water-level and low water-level limit controls shall be so constructed that they will not be damaged by water levels above or below the operating range. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 39 | The low water-level limit control shall have independent connections to the boiler. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | Water-level controls shall be so constructed that the water inlet valve cannot feed water into the boiler through the float chamber. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 41 | No outlet connection shall be placed on

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42 | For controls that are external to the boiler drum, the connections shall be fitted with shut-off valves locked and sealed in the open position and attached directly to the boiler drum. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Auxiliary Systems | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 43 | Subject to item 44, pumps and other components essential for main propulsion engine operation shall have stand-by pumps and components, and for ships of more than 150 tons gross tonnage, the stand-by pumps and components shall be arranged to start up automatically on failure of the operating pumps or other components. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 44 | In multi-engined ships where engines have integral pumps, a spare pump readily available for installation may be used in lieu of an automatic-starting stand-by pump. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 | Air compressors, refrigeration systems and other ship service systems that are essentially independent and self-controlled need not be controlled from a remote control location. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 46 | Bilge water high-level audible and visual alarms shall be fitted at the central control location in accordance with subitem 65(f)(vi) and shall monitor the following bilges:

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 47 | The bilge pumping systems shall be arranged to function for a reasonable period after the sounding of the bilge high-level alarm taking into account the size of the space bilges. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48 | Where automatic bilge pumps are fitted

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 49 | Subject to item 50, the fire control system shall incorporate at least one fire pump capable of being controlled from the fire control location set out in subitem 14(e) of Division II. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | For ships of 150 tons gross tonnage or less a manual fire pump and its controls, including means of opening the sea valve, may be installed in a suitable location on the deck in lieu of a remote-controlled pump. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 51 | Where valves in essential systems are normally closed to prevent frost damage to exposed piping, the controls for the valves shall be in readily accessible locations. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 52 | Where remote controls for valves are fitted, valve status indicators shall be fitted at the locations for the valve controls and valves located in locations liable to be flooded shall be capable of operating when submerged. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 53 | Where machinery space watertight doors are fitted, controls shall be fitted in accordance with the Hull Construction Regulations. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 54 | Fuel oil service tanks shall be capable of holding sufficient fuel for the total period of the normal ship operational route or for 24 hours normal operation, whichever is the lesser, at full power, except that where provision is made for automatic filling, the period may be reduced to eight hours. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 55 | If fuel tanks are required to be heated, fuel oil temperature shall be monitored and thermostatically controlled or the fuel tanks shall be fitted with a high-temperature audible and visual alarm in accordance with subitem 65(f)(iii). | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Remote Monitors | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 56 | The central control location shall include monitoring indicators as set out in items 65 and 66. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 57 | Where continuously reading indicators are impracticable, demand display types may be fitted. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 58 | Direct reading indicators shall be fitted at the location of the machinery. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 59 | Where the control system automatically shuts down machinery for any reason, regaining of control following correction of the fault shall not be possible without reset action and without bringing the control to the stop position. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | Alarms associated with machinery control and safety shall be clearly distinguishable from fire-alarms and, where possible, the arrangements of the alarms shall be such that the alarm is activated before failure and shut-down occurs. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 61 | Where alarms are displayed as group alarms, provision shall be made to identify each alarm at the central control location. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 62 | For the detection of transient faults that are subsequently self-correcting, alarms shall lock in until they are accepted. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 63 | The alarm system shall be capable of being tested during normal machinery operation. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 64 | Disconnection or manual overriding of any part of the alarm system shall be clearly indicated. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Remote Monitoring Indicators | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 65 | Where applicable and subject to item 66, the following monitors and audible and visual alarms shall be fitted at the central control location:

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 66 | For ships of 150 tons gross tonnage and less, only the following monitors and alarms shall be fitted at the bridge control location:

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ships Exempted From Carrying Watchkeeping Engineers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 67 | Ships exempted from carrying watchkeeping engineers under the Safe Manning Regulations where at least one engineer is required to be aboard shall be

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PARTS II to IV[Repealed, SOR/2021-135, s. 76]

- SOR/2015-161, ss. 17, 18(F), 19(F), 20(E)

- SOR/2017-14, s. 411

- SOR/2021-135, s. 76

SCHEDULE IXNon-Structural Tanks, Short Flexible Hoses and Rigid Plastic and Fibre-Reinforced Plastic Piping and Components

PART I(Section 4)Design Specifications

DIVISION IApplication

| Item | Application |

|---|---|

| 1 | This Schedule applies to non-structural tanks having a capacity of 4 500 L or less. |

| 2 | Non-structural tanks having a capacity of more than 4 500 L shall be designed, constructed and installed in accordance with the Hull Construction Regulations. |

DIVISION iiSpecifications

| Item | Requirements |

|---|---|

| Non-Structural Tanks of 4 500 L or Less Capacity | |

| 1 | Non-structural tanks shall

|

| 2 | Unsupported flat surface areas for different thickness plates of non-structural tanks shall be determined by interpolation or extrapolation. |

| 3 | Depending on the size and configuration of a non-structural tank, the tank may be required to be fitted with baffles. |

| Short Flexible Hoses | |

| 4 | Short flexible hoses shall be used where expansion and vibration may be encountered. |

| 5 | Short flexible hoses shall not be used in the correction of misalignment, except for connection of boiler fuel burners and other removable components. |

| 6 | Guards shall be fitted on large diameter pipes to reduce the flow of fluid leakage to within the capacity of the space bilge pumps. |

| 7 | Guards shall be fitted to prevent contact of leaking fluid with surfaces where a hazard may result. |

| 8 | Short flexible hoses shall be adequate for intended use. |

| Rigid Plastic and Fibre Reinforced Plastic Piping and Components | |

| 9 | Except in accommodation spaces, service spaces and control locations, piping and components of rigid plastic or fibre reinforced plastic may be used in

|

| 10 | Piping and components of rigid plastic or reinforced plastic shall not be used

|

| 10.1 | Despite items 9 and 10, plastic piping referred to in sections 114 and 226 of the Vessel Fire Safety Regulations may be used. |

| 11 | Piping and components of rigid plastic or reinforced plastic shall be protected from

|

| 12 | Allowance shall be made for expansion in piping systems. |

| 13 | Sea inlet and overboard discharge valves shall be of suitable metal construction where connected to rigid plastic or fibre reinforced plastic piping and the piping shall not be installed outboard of the valves. |

| 14 | When passing through a steel water-tight or fire control bulkhead, a steel spool-piece shall be attached to the bulkhead or deck and, at a water-tight bulkhead or deck a metallic shut-off valve shall be installed immediately adjacent to the spool-piece except that no valve is required on ballast or fresh water piping located within ballast or fresh water tanks. |

| 15 | Remote controls operable from above the bulkhead deck shall be fitted to the shut-off valve except where

|

| 16 | When passing through a bulkhead or deck material other than steel, the installation shall be such that the fire, watertight and structural integrity of the bulkhead or deck is not diminished due to penetration. |

PARTS II to IV[Repealed, SOR/2021-135, s. 77]

- SOR/2015-161, ss. 21(F), 22 to 24(E)

- SOR/2017-14, s. 415

- SOR/2021-135, s. 77

SCHEDULE XSteam, Boiler Water and Cooling Water Systems

PART I(Section 4)Design Specifications

| Item | Requirements |

|---|---|

| 1 | Steam pipes and connected components through which steam passes shall be designed, constructed and installed to withstand the maximum working stresses to which they may be subjected. |

| 2 | Means shall be provided for draining every steam pipe in which dangerous water-hammer action may occur. |

| 3 | Where a steam pipe or component may receive steam from any source at a higher pressure than that for which it is designed, it shall be fitted with a suitable reducing valve, relief valve and pressure gauge. |

| 4 | Each steam generating system that provides services essential for the safety of the ship, or that could be rendered dangerous by the failure of its feed-water supply shall be fitted with at least two separate feed- water systems, including feed pumps, but a single penetration of the steam drum is acceptable. |

| 5 | Unless over-pressure is prevented by the pump characteristics, means shall be provided to prevent over-pressure in any part of the system. |

PARTS II to IV[Repealed, SOR/2021-135, s. 78]

- SOR/2015-161, ss. 25(E), 26(F)

- SOR/2021-135, s. 78

SCHEDULE XICompressed Air and Refrigerating Gas Systems

PART I(Section 4)Design Specifications

| Item | Requirements |

|---|---|

| 1 | Means shall be provided to prevent over-pressure in any part of compressed air and refrigerating gas systems and in water jackets or casings of compressors and coolers that may be subjected to over-pressure due to pressurized air or gas leakage. |

| 2 | Where necessary, engine starting compressed air arrangements shall be adequately protected against the effects of backfiring and internal explosion in the starting air pipes. |

| 3 | All discharge pipes from starting air compressors shall lead directly to the starting air receivers, and all starting pipes from the air receivers to main or auxiliary engines shall be entirely separate from the compressor discharge piping system. |

| 4 | Means shall be provided to reduce to a minimum the entry of oil into the air pressure systems and to drain those systems. |

| 5 | Where soldering is to be used for piping connections, the metal shall be silver solder. |

PARTS II to IV[Repealed, SOR/2021-135, s. 79]

SCHEDULE XIIFuel Oil Systems

PART I(Section 4)Design Specifications

| Item | Requirements |

|---|---|

| 1 | Subject to items 2 and 3, fuel oil for all fixed installations shall have a flash-point of not less than 60°C (closed cup test). |

| 2 | Fuel oil for fixed installations may have a flash-point of not less than 43°C (closed cup test) where

|

| 3 | Fuel oil for emergency generator service may have a flash-point of not less than 43°C (closed cup test). |

| 4 | Fixed fuel oil systems for helicopters and for non-fixed equipment shall have additional safety features taking into account the quantity of fuel carried and the hazardous properties of the fuel. |

| 5 | Small approved portable containers holding fuel oil with a flash-point of lower than 43°C shall

|

| 6 | For ships operating in extremely cold conditions with exposed fuel oil piping to the emergency generator from an external deck-mounted fuel tank, means shall be taken so that the fuel oil viscosity will not adversely affect oil flow and where warming systems are used, the system shall incorporate a heat-limiting device to ensure that the oil is not heated to a temperature exceeding 20°C. |

| 7 | The ventilation of spaces in which fuel oil is used shall be sufficient to prevent accumulation of oil vapour. |

| Tanks | |

| 8 | Fuel oil shall not be stored in the forepeak and the tanks shall, as far as practicable, form part of the ship structure. |

| 9 | Where fuel oil tanks, except double bottom tanks, are located adjacent to machinery spaces of category A out of necessity, they shall have a common boundary, where practicable, with the double bottom tanks, and the area of the tank boundary common with the machinery spaces of category A shall be kept to a minimum. |

| 10 | Where practicable, the use of non-structural fuel oil tanks shall be avoided, but where used such tanks shall

|

| 11 | No fuel oil tank shall be located where spillage or leakage from the tank creates a hazard by falling on heated surfaces. |

| 12 | Fuel oil tanks for cooking and cabin hot-air heating appliances shall not be installed in the same spaces as the appliances and the supply of oil to appliance burners shall be capable of being shut off from positions outside the spaces in which the appliances are fitted. |

| 13 | Quantities of fuel oil in tanks may be determined by

|

| 14 | Where fuel oil quantities in a tank are determined by means other than sounding pipes, the installation of the system shall be in accordance with the following requirements:

|

| 15 | Provision shall be made to prevent over-pressure in any fuel tank or system by means of

|

| 16 | Subject to item 17, every fuel oil pipe that if damaged would allow fuel oil to escape either by gravity or siphon action from a storage, settling or daily service tank located in a space above the double bottom shall be fitted with a cock or valve on the tank that is capable of being closed from a safe location outside the space. |

| 17 | In the case of deep tanks situated in any shaft or pipe tunnel or similar compact space, valves shall be fitted on the tanks and remote control may be operated by means of an additional valve outside the compact space. |

| 18 | Where an additional valve is fitted in the machinery space it shall be operable from outside that space. |

| Piping and Components | |

| 19 | As far as practicable, all parts of a fuel oil system containing heated oil under pressure exceeding 180 kPa shall be located so that defects and leakage can be readily observed. |

| 20 | Machinery space fuel oil piping and components shall be adequately illuminated. |

| 21 | Means shall be provided to prevent oil that may escape under pressure from a component from coming into contact with heated surfaces. |

| 22 | Drip trays with drains leading to a sludge oil tank shall be fitted under all components where leakage may occur. |

| 23 | Fuel oil pipes shall be of steel or similar fire and pressure-resistant material, except that short flexible hoses may be used in accordance with Schedule IX. |

| 24 | Flexible hoses and end attachments shall be of fire-resistant materials of adequate strength and shall be constructed in accordance with Schedule IX. |

| Incinerators, Cooking Ranges and Cabin Hot-Air Heating Appliances | |

| 25 | Printed manufacturer’s instructions for the proper installation, maintenance and operation of each fuel oil burning appliance shall be permanently mounted in a visible location adjacent to the appliance. |

| 26 | In addition to the instructions referred to in item 25, the following safety instructions shall be prominently posted in spaces, other than machinery spaces, where fuel oil burning appliances are located: “WARNING ENSURE THAT FRESH AIR VENTILATION SYSTEM IS IN OPERATION WHEN USING FUEL-BURNING APPLIANCE If leakage of fuel oil is suspected or detected, the following actions must be taken immediately:

|

PARTS II to IV[Repealed, SOR/2021-135, s. 80]

- SOR/95-372, s. 7(F)

- SOR/2015-161, ss. 27(F), 28(E)

- SOR/2021-135, s. 80

SCHEDULE XIIILiquefied Petroleum Gas Fuel Systems

PART I(Section 4)Design Specifications

DIVISION IApplication

| Item | Description of Appliances |

|---|---|

| 1 | This Schedule applies to the following galley and cabin-heating appliances aboard non-passenger ships:

|

DIVISION IISpecifications

| Item | Requirements |

|---|---|

| 1 | Gas fuel shall have a distinctive odour to indicate the presence of gas down to a concentration of 20 per cent of the lower explosive limit of the gas in the air. |

| 2 | No liquefied petroleum gas fuel system of a type other than the vapour withdrawal type shall be installed or used in a ship. |

| 3 | Gas fuel cylinders and regulating and safety devices shall be securely fastened and so located that escaping vapour cannot reach bilges, machinery spaces, accommodation or other enclosed spaces. |

| 4 | Location of gas fuel cylinders, regulation arrangements and relief valve outlets shall be located only on open decks, on cabin tops, outside cockpits or inside housings that are gas-tight to the hull interior. |

| 5 | Appliances shall be installed in accordance with the manufacturer’s instructions and shall be securely fastened. |

| 6 | Appliances shall be connected in a manner that prevents undue strain on the piping. |

| 7 | Only liquefied petroleum gas fuel cylinders that meet the requirements of the Transport of Dangerous Goods Directorate of the Department of Transport or the Interstate Commerce Commission of the United States shall be used. |

| 8 | Liquefied petroleum gas fuel system components and piping shall have a design working pressure of not less than 1 725 kPa. |

| Piping Systems | |

| 9 | Gas fuel piping shall

|

| 10 | Gas fuel piping shall not be used as part of any electrical circuit or grounding system. |

| 11 | Gas fuel piping shall not be used as support or restraint for any item or fitting that is not part of the gas system. |

| 12 | Any valves, regulators or other fittings exceeding 0.5 kg mass per 6 mm of pipe outside diameter shall have their mass supported by means other than the gas piping. |

| 13 | Gas fuel piping shall be of a sufficient diameter to provide a sufficient supply of gas fuel to meet demand pressures at the point of use and the pressure drop between the regulator and the appliance shall not exceed 10 per cent. |

| 14 | High-pressure liquefied petroleum gas fuel piping between the gas storage cylinders and the regulators shall have a minimum wall thickness of 1.24 mm and the low-pressure gas fuel piping between the regulators and the gas-burning appliances shall have a minimum wall thickness of 0.81 mm. |

| 15 | Liquefied petroleum gas fuel piping shall

|

| 16 | Short reinforced flexible hoses and couplings used to connect the gas fuel piping system to a cylinder or gimballed appliance shall be of a type referred to in item 24. |

| 17 | Short reinforced flexible hoses shall be of the minimum practicable length but not longer than 1 m and shall not extend from one cabin to another or pass through any bulkheads, partitions, deck heads or decks. |

| Gas Storage Cylinders | |

| 18 | No gas fuel storage cylinder that permits gas in liquid form to enter any other part of the gas system shall be used. |

| 19 | Each liquefied petroleum gas fuel storage cylinder shall have a manually operated screw-down shut-off valve mounted directly on the cylinder outlet. |

| 20 | The manually operated screw-down shut-off valve shall be fitted with a spring-loaded safety device and with a fusible plug designed to yield when the cylinder has been emptied of liquefied petroleum gas by the relief valve under exposure to excessive heat. |

| 21 | The shut-off valve, the spring-loaded safety device and the fusible plug referred to in item 20 shall each have direct communication with the vapour space of a gas fuel storage cylinder. |

| 22 | A multiple-cylinder gas fuel system shall be fitted with a manually operated two-way positive shut-off manifold valve so arranged that the replacement of empty cylinders may be made without shutting down the flow of gas in the gas fuel system. |

| 23 | No electrical connections shall be made within a gas fuel storage cylinder enclosure. |

| Gas Fuel Components and Appliances | |

| 24 | Except for the gas fuel storage cylinders, only gas fuel components and appliances that meet the requirements of the Canadian Gas Association, the Compressed Gas Association, the Underwriters’ Laboratories of Canada or the Underwriters’ Laboratories Incorporated shall be used. |

| 25 | All valves and regulators embodied in the gas fuel system for the purpose of pressure relief, regulation or control of gas pressure and flow rates shall be securely mounted in a position readily accessible for operation, inspection, maintenance and testing, and shall be protected against physical damage. |

| 26 | The gas fuel system shall be fitted with a regulating device adjusted to release gas to the consuming appliance at a pressure not in excess of 4.5 kPa. |

| 27 | The low-pressure side of all regulators in the gas fuel system shall be protected against excessive pressure by means of a suitable relief valve that is fitted to the regulator and set to discharge at a pressure of not less than twice, and not more than three times, the delivery pressure. |

| 28 | All regulators in the gas fuel system shall be fitted with a pressure gauge located on the high-pressure side of the regulator. |

| 29 | A master packless shut-off valve controlling all burners simultaneously shall be installed on the console of each gas-burning appliance. |

| 30 | All appliances incorporating pilot-lights or other continuous-burning flame devices shall incorporate a flame failure device arranged to shut off the main and pilot gas in the event of flame failure. |

| 31 | Installation clearances between appliances and adjacent combustible material shall not be less than the clearances specified in the manufacturer’s instructions. |

| 32 | The piping and components in the gas fuel system shall be located so that gas leakage tests may be carried out at prescribed intervals as follows:

|

| Systems Installation for Ships Exceeding 24 m in Length | |

| 33 | Gas fuel storage cylinders and pressure-regulating and relief arrangements shall be

|

| 34 | Spare and empty gas fuel cylinders shall have valve outlets that are capped and may be stored within the metal enclosure or may be secured on the open deck in a location that is protected from damage, direct rays of the sun and heat by a suitable cover, and the enclosure or cover shall be ventilated to prevent the accumulation of gas. |

| 35 | The metal enclosure shall be designed to be closed at all times except when access is required to change cylinders in the gas system or to maintain equipment, and only the following items shall be stored in the enclosure:

|

| 36 | Gas fuel storage cylinder pressure-relief valves shall be vented away from the cylinders and, as far as practicable, upwards to prevent impingement of escaping gas onto the cylinders. |

| 37 | Gas fuel safety device vent outlets shall end at least 1.5 m from enclosed space openings and ventilation intakes. |

| 38 | Compartments containing liquefied petroleum gas-burning appliances that are located above the weather deck shall be ventilated by

|

| 39 | Compartments that contain liquefied petroleum gas-burning appliances or in which gas may accumulate and that are located entirely below the weather deck shall be ventilated by mechanical ventilation of the positive extraction type with a spark-proof fan and motor having sufficient capacity to effect at least 10 air changes per hour through ventilators leading to and from the open deck and the extraction duct of the ventilator shall extend from the deck level and the inlet duct of the ventilator shall extend to the deckhead of the compartment. |

| Systems Installation for Ships not Exceeding 24 m in Length | |

| 40 | Gas fuel storage cylinders and pressure-regulating and relief arrangements shall be

|